In general, packaging machinery has an expected lifespan on the order of 10 to 15 years under normal industrial use. High-quality machines from reputable manufacturers, maintained well, often reach the upper end of this range or beyond. In fact, some well-maintained packaging machines can remain in service for 20+ years, especially if they are built robustly and receive proper care. Conversely, poorly maintained or low-quality equipment may fail much sooner, sometimes in just 5–10 years.

Typical Lifespan by Machine Type

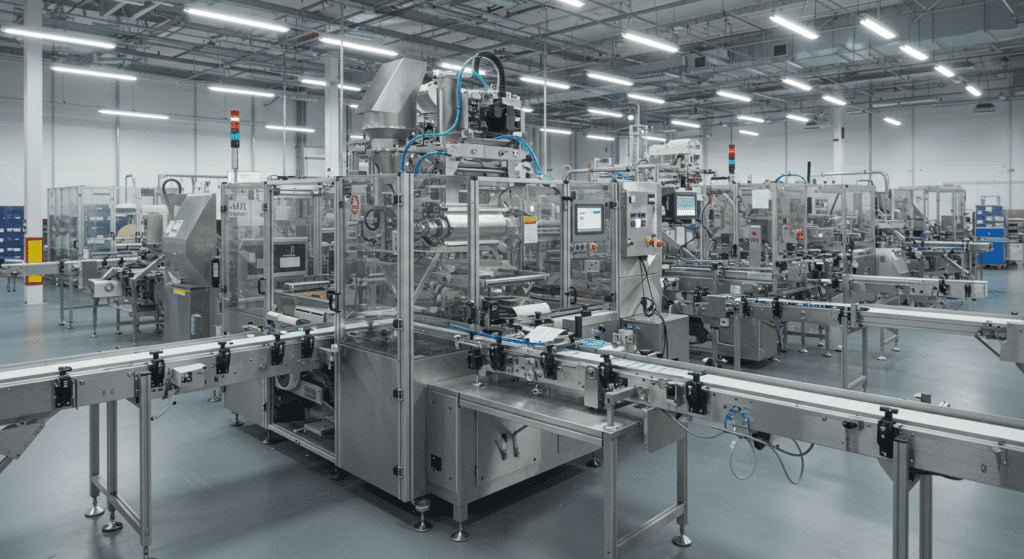

Form-Fill-Seal (FFS) Machines

Form-fill-seal machines form packaging from roll stock, fill it with product, and seal it in one automated process. They are designed for high-volume continuous operation.

These machines are often expected to last around a decade or more in active service. Industry guides generally cite a lifespan on the order of 10–20 years for FFS packaging machines

, assuming regular maintenance. In practice, many manufacturers plan for about 10–15 years of useful life before a major rebuild or replacement.

For example, the UK Process and Packaging Machinery Association notes that packaging equipment life expectancy is usually in the “10 to 15 years” range, which applies to FFS systems as well.

Shrink Wrap Machines

Shrink wrap machines (and related wrapping equipment such as shrink tunnels and heat sealers) typically have a somewhat shorter expected life, especially for smaller or entry-level units.

With proper maintenance, a shrink wrap machine usually lasts approximately 5 to 10 years in operation. Lower-cost manual or semi-automatic shrink wrappers may be closer to the 5-year mark, whereas heavy-duty industrial shrink wrapping systems can approach or exceed 10 years of service.

Blister Packaging Machines

Blister packaging machines form plastic cavities, insert products, and seal them with backing material.

A typical lifespan of roughly 10 to 20 years for pharmaceutical blister pack machines under good maintenance regimes. In practice, many blister packaging lines run for about 10–15 years as frontline production equipment.

Vacuum Sealing Machines

Vacuum sealing machines (vacuum packagers) exhibit a wide lifespan range, largely dependent on their build quality and duty cycle.

On the low end, small budget vacuum sealers or light-duty models might only last on the order of 5 years of regular use before needing significant repair or replacement. In contrast, industrial-grade vacuum packaging machines built with robust components can last for 20 years or more.

Other Packaging Equipment

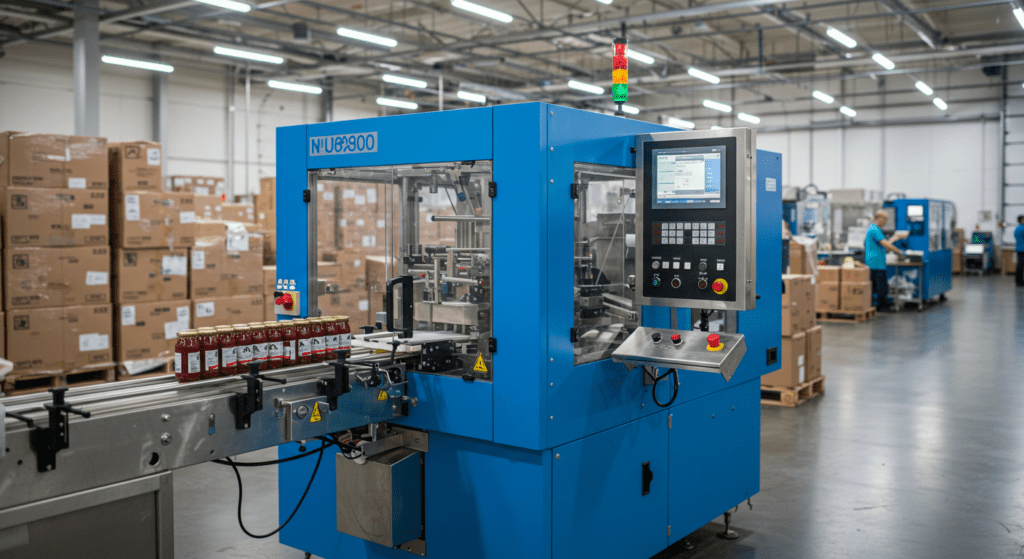

- Case packers function reliably for 15 to 20 years. These machines automatically pack products into cases or boxes.

- Cartoners maintain effectiveness for 12 to 17 years on average. These machines erect cartons, insert products, and seal them. High-speed cartoners operating at over 300 cartons per minute may have shorter lifespans due to increased mechanical stress.

- Palletizers typically operate for 20 to 25 years. These robust machines stack cases or products onto pallets.

- Labelers have a useful life of 10 to 15 years. These machines apply labels to products or packages.

- Capping machines function effectively for 12 to 18 years. These machines apply and tighten caps on bottles or containers.

Factors Influencing Useful Life

Quality

The initial build quality determines 60% of a packaging machine’s lifespan. High-quality machines built with durable materials (e.g. stainless steel frames, heavy-duty components) and proven design tend to last significantly longer. Cheaper or lightweight models may have weaknesses that lead to earlier failures.

Operating Conditions

The conditions in which the equipment operates will influence wear and tear. Harsh environments, such as exposure to excessive heat, moisture/humidity, dust, corrosive chemicals, or washdown conditions can shorten a machine’s life by causing corrosion or accelerated wear.

Maintenance

Regular maintenance extends packaging machine life by 40% to 60%. Daily cleaning prevents product buildup that causes premature wear. Weekly lubrication of moving parts reduces friction and heat generation. Monthly inspections catch small problems before they become major failures.

Usage Intensity

Machines rated for intermittent duty suffer rapid wear when run continuously. A machine designed for 50% duty cycle operating at 90% duty may lose half its expected lifespan.

Technological Obsolescence and Upgrades

Packaging machines become technologically obsolete before mechanical failure in many cases. New packaging formats, materials, or regulations may require capabilities that older machines lack. The average technological lifespan is 10 to 12 years before major upgrades become necessary.

How to Increase Packaging Machine Life

Implement a Comprehensive Maintenance Program

Create detailed maintenance checklists for daily, weekly, and monthly tasks. Train operators to perform basic maintenance like cleaning and visual inspections. Schedule professional servicing based on actual operating hours rather than calendar dates.

Optimize Operating Parameters

Run machines within recommended speed and load ranges. Reduce operating speed by 10% to 20% during non-peak periods to decrease wear. Monitor motor temperatures and vibration levels to detect problems early.

Adjust machine settings for different products to minimize stress. Use the gentlest settings that still achieve quality standards. Program soft-start and soft-stop sequences to reduce mechanical shock during startup and shutdown.

Maintain Optimal Environmental Conditions

Install climate control systems to maintain stable temperature and humidity. Use air filtration to remove dust and contaminants. Position machines away from sources of vibration or electromagnetic interference.

Create protective enclosures for machines in harsh environments. Apply protective coatings to exposed metal surfaces. Install drainage systems to prevent water accumulation around equipment.

Invest in Quality Spare Parts

Stock critical spare parts to minimize downtime. Use only OEM or certified replacement parts that meet original specifications. Replace wear parts like belts, chains, and bearings on schedule rather than waiting for failure.

Train Personnel Properly

Provide comprehensive operator training on proper machine operation. Teach troubleshooting skills to identify problems early. Create standard operating procedures for all routine tasks.