Blow Fill Seal (BFS) and Form Fill Seal (FFS) are two automated packaging technologies that create, fill, and seal containers in one continuous process. While both technologies share some similarities, they serve different purposes and industries.

The main difference lies in their applications and processes. BFS is primarily used for sterile pharmaceutical liquids and creates containers from plastic resin. FFS is more versatile, used across food, pharmaceutical, and consumer goods industries, and typically works with pre-made plastic films.

What is BFS

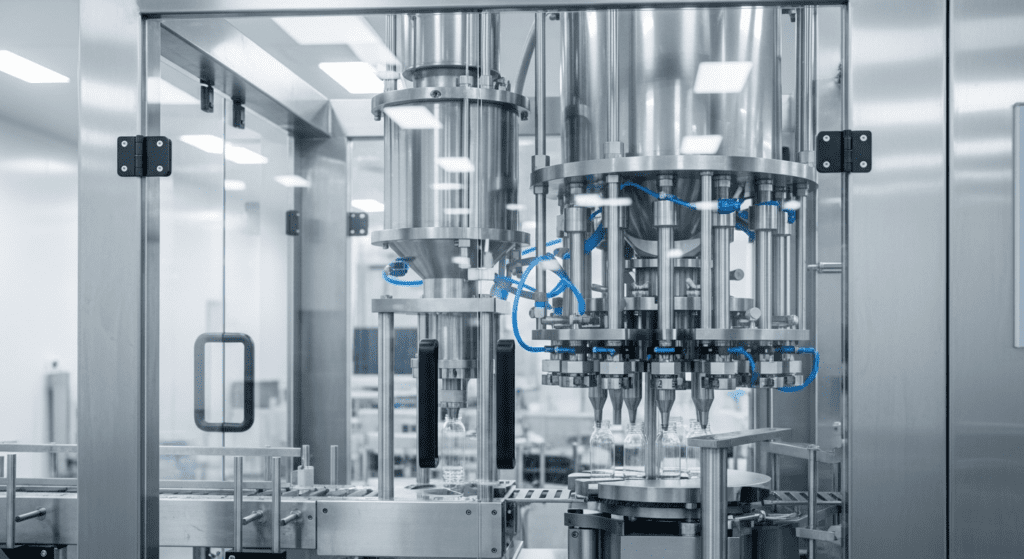

Blow Fill Seal (BFS) is an automated manufacturing process that forms plastic containers, fills them with product, and seals them in one continuous operation inside a sterile environment.

The BFS process takes just 10-15 seconds to complete. It starts when plastic resin granules are heated to over 160°C and extruded into a hollow tube called a parison. This parison is then captured by molds that shape it into the desired container form using sterile compressed air or vacuum.

The entire process happens without human intervention in a closed, sterile chamber. This dramatically reduces contamination risks compared to traditional packaging methods.

What is FFS

Form Fill Seal (FFS) is an automated packaging technology that forms containers from flat plastic film, fills them with product, and seals them in a single machine operation.

FFS machines start with a roll of flexible plastic film. The film is unwound and formed into the desired package shape – whether that’s a pouch, bag, or tray. The formed container is then filled with product and sealed, all in one continuous process.

The Difference Between Blow Fill Seal (BFS) and Form Fill Seal (FFS)

While both BFS and FFS are automated packaging technologies, they have significant differences in how they work and what they’re used for.

Package Types

BFS Containers:

BFS produces rigid or semi-rigid plastic containers. These include ampoules, vials, bottles, and even prefilled syringes. Container sizes range from tiny 0.1ml ampoules up to 1-liter bottles.

FFS Packages:

FFS creates flexible packages from film materials. Common formats include sachets, pouches, bags, and occasionally rigid trays. Package types include stand-up pouches, zipper bags, gusseted bags, and multi-compartment packages. FFS offers more variety in package styles but is limited to what can be formed from flexible films.

Materials

BFS Materials:

BFS exclusively uses thermoplastic resins, primarily low-density polyethylene (LDPE), high-density polyethylene (HDPE), and polypropylene (PP).

FFS Materials:

FFS works with a wider range of flexible materials. These include polyethylene, polypropylene, laminated films, and even paper-based materials.

Sterility

BFS Sterility:

BFS is inherently an aseptic process. The container is formed, filled, and sealed within a sterile environment in seconds. The high temperature of the plastic during forming essentially sterilizes the container as it’s created. This makes BFS ideal for sterile pharmaceutical products without requiring additional sterilization steps.

FFS Sterility:

Standard FFS machines don’t provide the same level of sterility assurance. While aseptic FFS systems exist for pharmaceutical applications, they require additional sterilization steps like hydrogen peroxide treatment or steam sterilization of the film.

Speed/Efficiency

BFS Speed:

BFS machines can produce up to 7,000 units per minute for small containers. The cycle time is typically 10-15 seconds per set of containers.

FFS Speed:

FFS machines generally operate faster, especially VFFS systems that can reach speeds of 100-200 packages per minute.

Footprint

BFS Footprint:

BFS machines are compact, self-contained units. The entire forming, filling, and sealing process happens within one machine. A typical BFS machine might occupy 100-200 square feet.

FFS Footprint:

FFS lines tend to be longer due to the horizontal film travel path. VFFS machines have a smaller footprint than HFFS systems. A complete FFS line might require 500-1000 square feet.

Flexibility

BFS Flexibility:

BFS is limited to liquid and semi-liquid products that can be pumped. Molds can be changed to create different shapes and sizes. The technology handles various viscosities from water-thin to thick gels.

FFS Flexibility:

FFS wins on product versatility. It can package liquids, powders, granules, and solid items. Package formats are easily changed by adjusting forming tools. However, each product type might require different filling systems, adding complexity.

Cost

BFS Cost:

BFS machines have higher initial capital costs, often exceeding $1 million. However, operating costs are low since raw materials (plastic resin) are inexpensive. There’s no need to purchase pre-made containers. Labor costs are minimal due to automation.

FFS Cost:

FFS equipment costs vary widely based on complexity, from $50,000 for simple machines to $500,000 for sophisticated lines. Film materials cost more than raw resin but less than pre-made containers.

Regulatory

BFS Regulatory:

BFS has strong regulatory support in pharmaceuticals. The FDA recognizes it as an advanced aseptic process.

FFS Regulatory:

FFS faces different regulatory requirements depending on the application. Food packaging must meet FDA food contact regulations. Pharmaceutical FFS requires additional validation for sterility assurance.

Typical Applications

BFS Applications:

BFS dominates in sterile pharmaceutical liquids. Common products include preservative-free eye drops, nasal sprays, injectable drugs, respiratory medications, and IV solutions.

FFS Applications:

FFS serves diverse markets. In food, it packages snacks, coffee, sauces, and frozen foods. Pharmaceutical uses include powder medications and medical devices. Industrial applications cover chemicals, fertilizers, and pet food.

Contamination Risk

BFS Contamination Risk:

BFS offers the lowest contamination risk for sterile products. The closed, automated process eliminates human intervention during critical steps. The brief exposure time (seconds) minimizes airborne contamination opportunities.

FFS Contamination Risk:

Standard FFS has higher contamination potential due to the open film path and longer exposure times.

Environmental Impact

BFS Environmental Impact:

BFS uses minimal packaging material since containers are formed to the exact size needed. The single-material construction (usually polyethylene) simplifies recycling. Energy consumption is higher due to plastic melting, but the compact process reduces overall facility energy needs. Scrap plastic can be reground and reused.

FFS Environmental Impact:

FFS can use recyclable and biodegradable films, offering more sustainable material options. Multi-layer laminates complicate recycling but provide better product protection with less material. The lower processing temperatures save energy. Film waste is minimal with proper setup.