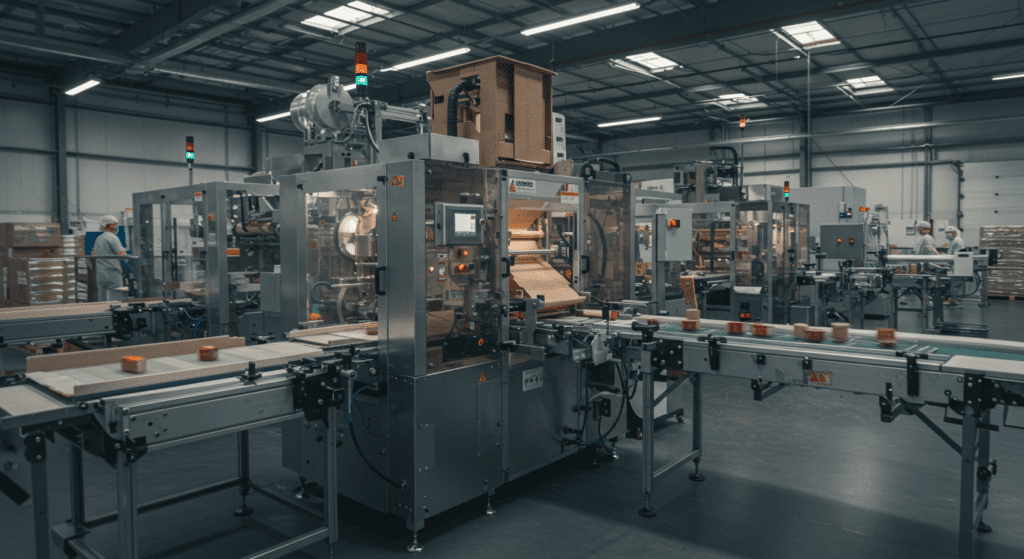

Packaging machinery automates the process of enclosing and protecting products for distribution. It includes machines for filling, sealing, labeling, and wrapping. These machines operate using sensors, conveyors, and programmable controls to ensure speed, accuracy, and consistency during packaging across various product types.

What Is Packaging Machinery

Packaging Machinery consists of automated systems that prepare products for distribution, storage, sale, and use. These machines handle everything from filling containers with products to sealing, labeling, and preparing them for shipment. They operate through mechanical, electrical, and pneumatic systems that work together to transform raw materials and products into finished, packaged goods ready for consumers.

Packaging Operation Process

1. Container Preparation

Container preparation starts the packaging process by creating or preparing the package that will hold the product. Machines form boxes, bottles, pouches, or other containers from flat materials or preformed shapes.

2. Conveying

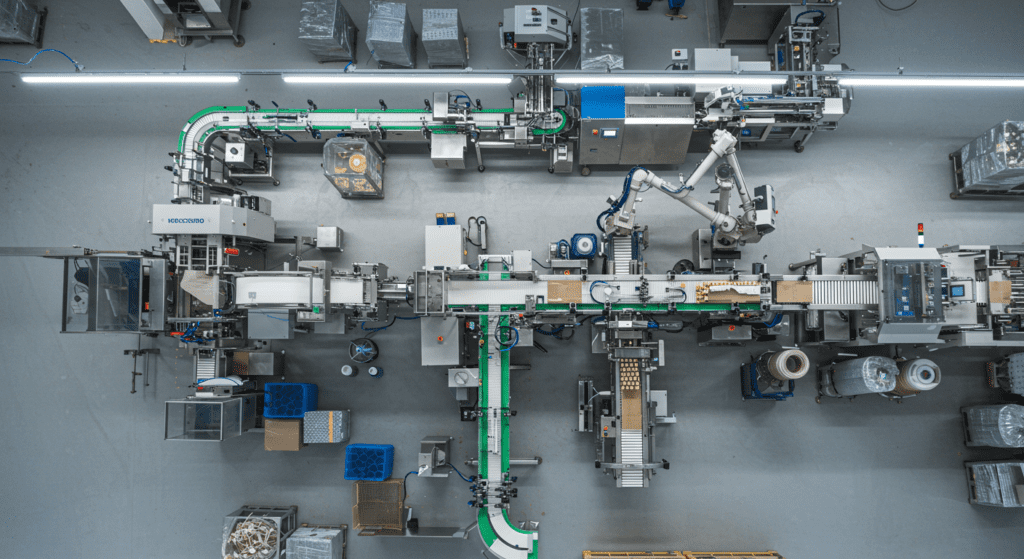

Conveying systems move products and containers through each stage of the packaging line. A typical conveyor system includes straight sections, curves, transfers, and diverters that guide products to different packaging stations.

3. Filling

Filling machines dispense precise amounts of product into containers.

4. Closing and Sealing

Closing and sealing operations secure the product inside its container. A capping machine applies torque of 15-25 inch-pounds to twist bottle caps, while a heat sealer creates hermetic seals on pouches at temperatures of 300-400°F.

5. Labeling and Coding

Labeling machines apply product information, branding, and regulatory details to packages. A pressure-sensitive labeler places adhesive labels on 200 bottles per minute with ±1mm accuracy, while a sleeve labeler shrinks plastic sleeves around containers using 350°F steam tunnels. Coding systems print batch numbers, expiration dates, and barcodes directly onto packages.

6. End-of-Line Operations

End-of-line operations prepare packaged products for distribution. Case packers group bottles into cardboard cases, while palletizers stack cases onto wooden pallets in predetermined patterns.

Quality control happens here too. Checkweighers verify that each package contains the correct amount of product, rejecting items that fall outside a tolerance range.

Types of Packaging Machinery and How Do They Work

The main types of packaging machinery include filling machines, sealing machines, labeling machines, wrapping machines, and cartoning machines.

Form-Fill-Seal (FFS)

Form-fill-seal machines create packages from roll stock material, fill them with product, and seal them in one continuous operation:

- Vertical Form-Fill-Seal (VFFS): VFFS machines pull film downward over a forming collar that shapes it into a tube. The machine seals the bottom, fills the pouch with product through the open top, then seals the top and cuts the package.

- Horizontal Form-Fill-Seal (HFFS): HFFS machines form packages horizontally, making them ideal for products that need careful handling. The film travels horizontally through the machine while forming pockets that receive products from above or the side.

- Thermoform-Fill-Seal (TFFS): TFFS machines heat plastic sheet material to 250-350°F, then use vacuum or pressure to form it into cavities. Products drop into these formed pockets before a top film seals the package.

Filling & Dosing

Filling machines ensure accurate product quantities in each package:

- Liquid Fillers (Piston, Pump, Gravity): Piston fillers draw liquid into a cylinder then push it out in measured amounts, handling viscous products like honey at 10-50 cycles per minute. Pump fillers move thin liquids continuously at rates up to 300 containers per minute. Gravity fillers use tank height to create consistent flow for free-flowing liquids like water or juice.

- Auger Fillers: Auger fillers use rotating screws to move powdered or granular products. The auger turns a specific number of rotations to dispense exact amounts of products like flour, spices, or pharmaceutical powders.

- Multi-Head Weighers: Multi-head weighers use 10-24 individual weighing buckets that work together. A computer calculates which combination of buckets equals the target weight, achieving accuracies of ±0.1-1.0 grams at speeds up to 120 weighments per minute for products like candy, nuts, or frozen foods.

Closing & Sealing

These machines secure packages after filling:

- Capping Machines (Spindle, Chuck, Snap): Spindle cappers use rotating discs to grab and tighten threaded caps as containers pass through. Chuck cappers grip one cap at a time for precise torque control on products like pharmaceuticals. Snap cappers press caps straight down for push-on closures at speeds up to 300 bottles per minute.

- Heat Sealers: Heat sealers use heated bars or bands to melt plastic layers together. Impulse sealers heat only during the sealing cycle for thin materials, while constant heat sealers maintain temperature for thicker films.

- Vacuum Sealers: Vacuum sealers remove air from packages before sealing to extend shelf life. Chamber vacuum sealers evacuate 99.9% of air in 20-45 seconds, ideal for meat and cheese products.

Labeling & Coding

These systems add product identification and information:

- Pressure-Sensitive Labelers: Pressure-sensitive labelers peel adhesive labels from a backing and apply them to products using a tamp pad or air blast. Wrap stations can apply labels to round containers at 360° while maintaining ±1mm placement accuracy at speeds up to 1,000 products per minute.

- Sleeve Labelers: Sleeve labelers cut plastic sleeve material from a roll and open it with vacuum. The sleeve slides over the container before passing through a heat tunnel that shrinks it to conform to the package shape. This creates 360° decoration coverage for uniquely shaped containers.

Wrapping & Bundling

These machines group and protect multiple items:

- Stretch Wrappers (Turntable, Rotary Arm): Turntable wrappers rotate pallets while dispensing stretch film, applying 15-25 wraps in 2-3 minutes. Rotary arm wrappers keep the load stationary while the film carriage rotates around it, better for unstable loads. Both types pre-stretch film 200-300% to reduce material usage.

- Shrink Wrappers: Shrink wrappers enclose products in polyolefin or PVC film, then pass them through a heat tunnel at 300-350°F. The film shrinks 40-50% to create tight, clear packages. Beverage multipacks and retail product bundles commonly use this method at speeds of 15-100 packages per minute.

Cartoning & Case Packing

These machines create secondary packaging:

- Cartoning Machines (Horizontal, Vertical): Horizontal cartoners push products sideways into cartons, ideal for bottles, tubes, and blister packs at 50-300 cartons per minute. Vertical cartoners drop products down into boxes, better for bags and pouches. Both types use mechanical fingers or vacuum cups to open cartons from flat blanks.

- Case Erectors & Packers: Case erectors form shipping cases from flat corrugated blanks using vacuum cups and folding mechanisms. They seal bottoms with tape or hot melt adhesive at 15-30 cases per minute. Case packers then load products using pick-and-place systems or robotic arms before sealing the tops.

End-of-Line

These systems prepare shipments:

- Palletizers (Conventional, Robotic): Conventional palletizers use layer-forming tables to arrange products in rows, then slide complete layers onto pallets. They handle 20-40 cases per minute with consistent products. Robotic palletizers use articulated arms to place mixed products in complex patterns, adapting to 5-15 different SKUs per pallet.

Inspection

Quality control systems ensure product safety:

- Checkweighers: Checkweighers use load cells to weigh products at full production speed. They detect and reject packages outside acceptable weight ranges within ±0.1-5 grams accuracy.

- Metal Detectors: Metal detectors use electromagnetic fields to identify ferrous, non-ferrous, and stainless steel contaminants as small as 0.8mm. They inspect 300-600 packages per minute and automatically reject contaminated items using air blasts or pusher arms.

What Is the Difference Between Packaging Machinery and Packaging Equipment

Packaging machinery refers to complete automated systems that perform multiple packaging functions. A form-fill-seal machine represents packaging machinery because it creates packages, fills them, and seals them through integrated operations.

Packaging equipment describes individual tools or devices that perform single functions within the packaging process. A hand-held tape dispenser, a tabletop heat sealer, or a semi-automatic capping machine qualify as packaging equipment.

The key distinction lies in complexity and integration. Machinery forms complete production lines with conveyor systems, multiple stations, and central control systems. Equipment serves as standalone units that require manual product handling between operations.

What Is the Difference Between Packaging Machinery and Packing Machinery

Packaging machinery and packing machinery serve different stages in the distribution process. Packaging machinery handles primary packaging that directly contacts the product. A bottle filler that puts shampoo into containers or a flow wrapper that seals individual candy bars operates as packaging machinery.

Packing machinery manages secondary and tertiary packaging for shipping and distribution. Case packers that group 12 bottles into cardboard boxes or stretch wrappers that secure pallets for transport function as packing machinery. These machines handle already-packaged products.

How to Choose the Right Packaging Machinery

Choose the right packaging machinery by matching machine type to product needs, considering factors like production speed, package size, automation level, and budget.

- Define your production volume requirements: Calculate current daily output and projected growth over 5 years. A bakery producing 1,000 loaves daily needs different machinery than one making 10,000 loaves.

- Analyze product characteristics: Consider size, weight, texture, and fragility. Liquid products need filling systems with drip-prevention, while powders require dust containment features.

- Establish your budget parameters: Include purchase price, installation costs, training expenses, and annual maintenance. Leasing options can reduce initial investment by 60-70%.

- Evaluate available floor space: Measure length, width, and ceiling height in your facility. Account for operator access, maintenance clearances, and material flow paths around the machine.

- Assess utility requirements: Verify electrical voltage (208V, 240V, or 480V), compressed air capacity (typically 80-100 PSI), and any steam or cooling water needs.

- Determine changeover flexibility: Multi-product operations need quick-change features. Tool-free adjustments can reduce changeover time from 2 hours to 15 minutes.

- Research maintenance and support: Local technical support reduces downtime. Check spare parts availability and typical lead times. Preventive maintenance contracts cost 5-10% of machine value annually.