Blow-Fill-Seal (BFS) is an automated aseptic process used to form, fill, and seal containers in a single operation. The machine blows pharmaceutical-grade plastic into a mold, fills it with liquid medication, and seals it—all under sterile conditions. BFS is widely used for unit-dose packaging of sterile liquids.

What is Blow-Fill-Seal (BFS)

Blow-Fill-Seal (BFS) is a manufacturing method that creates, fills, and seals plastic containers in one continuous process. This technology produces sterile containers in 10 to 15 seconds without any human contact.

The process happens inside a single machine. It starts with plastic pellets and ends with sealed containers filled with product.

BFS is mainly used for making small plastic bottles and vials. You’ll find these containers holding eye drops, nasal sprays, vaccines, and other medical products. The process works especially well for products that need to stay sterile.

BFS Process Steps

The BFS process follows seven main steps to turn plastic pellets into filled and sealed containers. Each step happens automatically in sequence.

1. Extrusion

The process starts by melting plastic pellets at temperatures between 350°F and 400°F. The melted plastic flows through a tube-shaped opening called a die.

This creates a hollow tube of hot plastic called a parison. The parison hangs down like a thick plastic straw.

2. Mold Closing

Metal molds quickly close around the hot plastic tube. These molds have the exact shape of the container you want to make.

The closing happens in less than one second. The molds grip the plastic firmly but don’t damage it.

3. Parison Cutting

A hot knife cuts the parison just above where the molds closed. This separates your container-to-be from the continuous flow of plastic above.

The cut happens cleanly and quickly. Any extra plastic gets recycled back into the system.

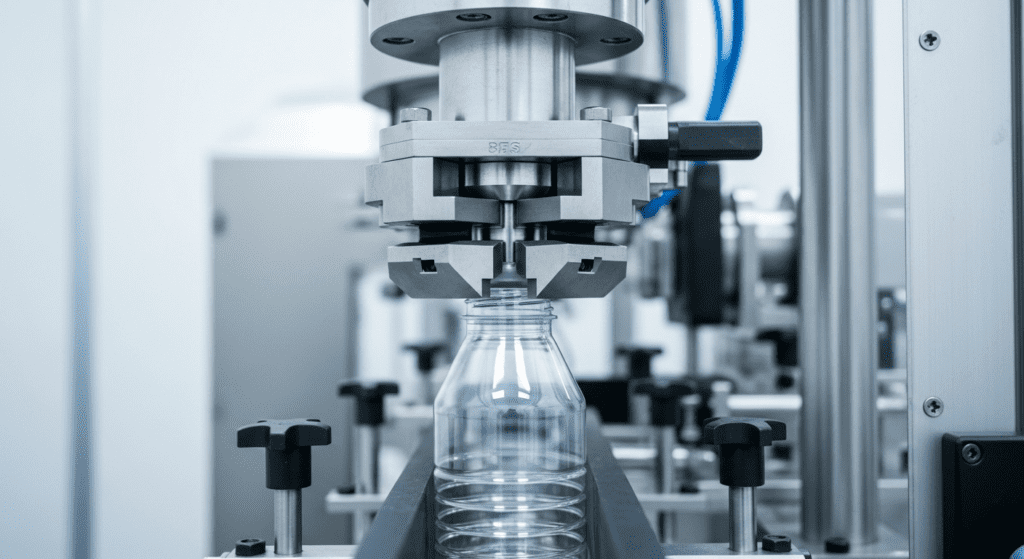

4. Blowing (Mold Inflation)

Sterile air or nitrogen gets blown into the parison through a small tube. The pressure inflates the soft plastic like a balloon.

The plastic expands until it touches all sides of the mold. This creates the final container shape in about 1-2 seconds.

5. Filling

A filling needle enters the formed container from the top. The product flows through this needle at a precise rate.

Typical fill speeds range from 100 to 600 containers per minute. The filling happens while the plastic is still warm and sealed inside the mold.

6. Mandrel Removal

The filling needle (also called a mandrel) pulls out of the container. This movement happens smoothly to avoid splashing the product.

The withdrawal takes less than half a second. A small opening remains where the needle was.

7. Sealing

The top of the container gets sealed while the plastic is still warm. The molds press the neck area together to create an airtight seal.

Some systems add a separate cap or closure at this stage. The sealed container then drops out of the molds onto a conveyor belt.

Types of Blow-Fill-Seal (BFS) Machines

BFS machines come in three main designs that suit different production needs.

Shuttle-Type Blow-Fill-Seal (BFS) Machines

Shuttle-type machines use molds that move back and forth like a shuttle. The parison stays in one spot while the molds slide horizontally to catch it.

These machines can produce 3,000-4,000 containers per hour. They work best for larger containers between 5ml and 1,000ml.

Shuttle machines offer great flexibility. You can change molds quickly to make different container shapes and sizes.

Rotary-Type Blow-Fill-Seal (BFS) Machines

Rotary machines have molds arranged on a rotating wheel or carousel. The wheel turns continuously, picking up new parisons at each station.

These are the fastest BFS machines, producing up to 15,000 containers per hour. They excel at making small containers under 50ml.

The continuous rotation means less downtime. However, they’re best suited for long production runs of the same product.

Linear-Type Blow-Fill-Seal (BFS) Machines

Linear machines arrange all processes in a straight line. Containers move from station to station on a conveyor system.

These machines produce 2,000-3,000 containers per hour. They handle medium to large containers from 10ml to 5,000ml.

Linear systems offer the most flexibility for container design. They can make complex shapes and multi-chamber containers that other types can’t.

Learn more about What is the Difference Between Blow Fill Seal (BFS) and Form Fill Seal (FFS)

Main Components of a BFS System

A BFS machine contains eight major components that work together to create finished containers.

Extruder and Melt Pump

The extruder melts plastic pellets and keeps them at the right temperature. It contains a large screw that mixes and pushes the melted plastic forward.

The melt pump controls exactly how much plastic flows to form each parison. It maintains steady pressure even when the extruder speed changes.

Blow Molds

Molds are made from aluminum or stainless steel blocks. They contain cooling channels that keep temperatures between 40°F and 60°F.

Blow/Inflation Unit

This system provides filtered, sterile air for forming containers. It includes compressors, filters, and pressure regulators.

Filling Manifold and Pumps

The filling system includes storage tanks, pumps, and distribution pipes. It keeps products at the right temperature and pressure.

Pumps can handle liquids from water-thin to honey-thick consistencies. They maintain accuracy within 0.5% of the target fill volume.

Sealing Station

This component creates the final closure on each container. It uses heat, pressure, or ultrasonic energy to weld the plastic together.

Cutting/Trimming Unit

Rotating knives or lasers remove excess plastic from containers. They create clean edges without generating particles.

Conveyors

Belt conveyors move containers through inspection and packaging.

Sterilization/Cleaning Systems

These systems clean molds and product paths between batches. They use steam, chemicals, or radiation depending on requirements.

Benefits of BFS

High Sterility

BFS achieves sterility levels that match or exceed other aseptic processes. The closed system prevents contamination from people or the environment.

Automation and Consistency

The entire process runs without human intervention. This eliminates variations caused by different operators.

Efficiency and Throughput

A single BFS machine produces 3,000 to 36,000 containers per hour. The process uses 40% less energy than blow molding plus separate filling. Production runs 24 hours a day with minimal downtime.

Reduced Cost and Waste

BFS cuts packaging costs by 20% to 50% compared to glass containers. It uses exactly the amount of plastic needed for each container.

Flexible Container Design

Manufacturers can create unique shapes for different products. Containers range from 0.1 ml eye droppers to 1,000 ml IV bags.

Eliminated Assembly Steps

Traditional filling requires separate steps for bottle making, cap making, filling, and capping. BFS combines everything into one process.

This eliminates the need to buy, ship, wash, and sterilize empty containers. It also removes the risk of mixing up different components.