VFFS (Vertical Form Fill Seal) machines create eight main types of bags, each designed for specific packaging needs and product characteristics. These bags range from simple pillow bags to complex stand-up pouches with special features.

| Bag Style | Seals & Structure | Stand-up? | Advantages | Disadvantages |

|---|---|---|---|---|

| Pillow (Back-Seal) | 3 seals: one vertical back (fin) or center seal + top & bottom horizontals | No | Very simple and fast to make; uses least film per bag; economical; full-area printing; high speed. | Doesn’t stand on its own; limited volume; less rigid protection; moderate shelf appeal. |

| Gusseted Pillow | As pillow + two side gussets folded at edges | Partial | Greater volume than pillow (holds bulkier loads); more stable base (can stand if filled); still high-speed. | Still not true stand-up; slightly more film than plain pillow; back graphics hidden; minor machine change. |

| 3-Side Seal | 3 seals on three edges (eliminates back seal) | No | Cheaper to produce; extra front-panel graphics area; easy case-packing. | Limited to smaller items; can’t stand; open end or perforated top; extra waste if tear-off required. |

| Quad Seal | 4 vertical seals (2 panels + 2 gussets) + flat bottom | Yes | Excellent shelf presence (stands erect); very strong (handles heavy fills); expandable volume (low empty space); 4-panel branding. | Complex/more expensive to form; more film required; needs skill to run; bottom tips when nearly empty. |

| Flat Bottom | 1 vertical (center or offset) + glued/folded bottom panel | Yes | Stands well; very wide face for labeling; strong shelf appeal; can include zip, valve, handles. | More material (bottom layers); slower form/seal cycle; moderate complexity. |

| Doypack (Stand-Up) | Bottom gusset or multi-fold base + usually a vertical back seal | Yes | Premium look; stands on its own; large panels (acts as “billboard”); reclosable; high consumer appeal. | Uses the most film; slower filling; higher unit and equipment cost; typically premade unless specialized VFFS. |

| Tetrahedron | 4 triangular seals forming a pyramid. | Yes (one face) | Eye-catching novelty; compact single-serve portion. | Very small capacity; specialized filling; unconventional shape (limited use cases). |

| Brick (Plow-Down) | Pillow bag with top folded down + sealed/taped | No (but brick form) | Extremely space-efficient for shipping; stable block shape; consumer reseal (tin-tie) option. | Extra sealing step; uses folded film (slightly more material); slower processing. |

Pillow Bag (Back-Seal Bag)

The pillow bag is the most common and economical VFFS bag type, featuring a vertical seal running down the back and horizontal seals at the top and bottom. This simple three-seal design creates a pillow-like shape when filled.

These bags work perfectly for snacks, coffee, candy, and frozen vegetables. The back seal design keeps the front panel clean for branding and product information.

Pillow bags typically cost 15-30% less than more complex bag styles. They run at speeds up to 120 bags per minute on standard VFFS machines.

Gusseted Pillow Bag

Gusseted pillow bags add expandable side panels to the basic pillow bag design, creating 25-40% more volume capacity. The gussets fold inward when empty but expand outward when filled with product.

This extra capacity makes gusseted bags ideal for bulky items like pet food, soil, or family-size snack portions. The expanded shape also provides better shelf stability than regular pillow bags.

Many coffee roasters prefer gusseted bags because they stand upright on store shelves. The side gussets can include one-way degassing valves for fresh-roasted coffee beans.

Three-Side Seal Bag

Three-side seal bags have seals on both sides and the bottom, with the top edge folded over from a single piece of film. This creates a flat, envelope-style package with no back seal.

These bags offer maximum front panel space for graphics and product visibility. Common applications include single-serve portions, sample packets, and medical device packaging.

The fold-over design eliminates one seal, reducing potential leak points by 25%. Three-side seal bags typically run at 60-80 bags per minute on VFFS equipment.

Quad-Seal (Four-Seal) Bag

Quad-seal bags feature four vertical corner seals that create a box-like shape with excellent stability. The design combines two gusseted sides with reinforced corners for maximum strength.

This heavy-duty construction handles weights up to 50 pounds for products like pet food, charcoal, or bulk grains. The flat bottom and straight sides allow efficient palletizing and shelf display.

Quad-seal bags use 30-50% more film than pillow bags but provide superior protection and presentation. The corner seals distribute weight evenly, reducing stress on any single seal point.

Flat-Bottom (Block-Bottom) Stand-Up Bag

Flat-bottom bags combine a rectangular base with vertical sides, creating a box-like container from flexible film. The bottom unfolds during filling to form a stable platform that stands without support.

These premium bags maximize shelf appeal for products like premium coffee, granola, or specialty foods. The wide base accommodates 20-35% more product than similar-height pillow bags.

The complex folding pattern requires specialized VFFS tooling and runs at slower speeds of 30-50 bags per minute. However, the professional appearance often justifies the higher production cost.

Stand-Up (Doypack) Pouch

Stand-up pouches feature a specially designed bottom gusset that expands to create a stable base. The unique W-shaped bottom seal allows the pouch to stand upright when filled while lying flat when empty.

These versatile pouches work excellently for liquids, powders, and solid products. Common applications include baby food, sauces, nuts, and personal care products.

Stand-up pouches can include convenient features like spouts, zippers, or tear notches. They typically reduce packaging material by 40-70% compared to rigid containers.

Tetrahedron Bag

Tetrahedron bags create a distinctive pyramid shape through perpendicular top and bottom seals. This unique geometry provides maximum volume with minimal material usage.

These eye-catching packages work well for single-serve portions of tea, spices, or bath salts. The triangular faces offer three display surfaces for branding.

The perpendicular sealing requires specialized VFFS jaws and precise film control. Production speeds typically range from 40-60 bags per minute due to the complex sealing sequence.

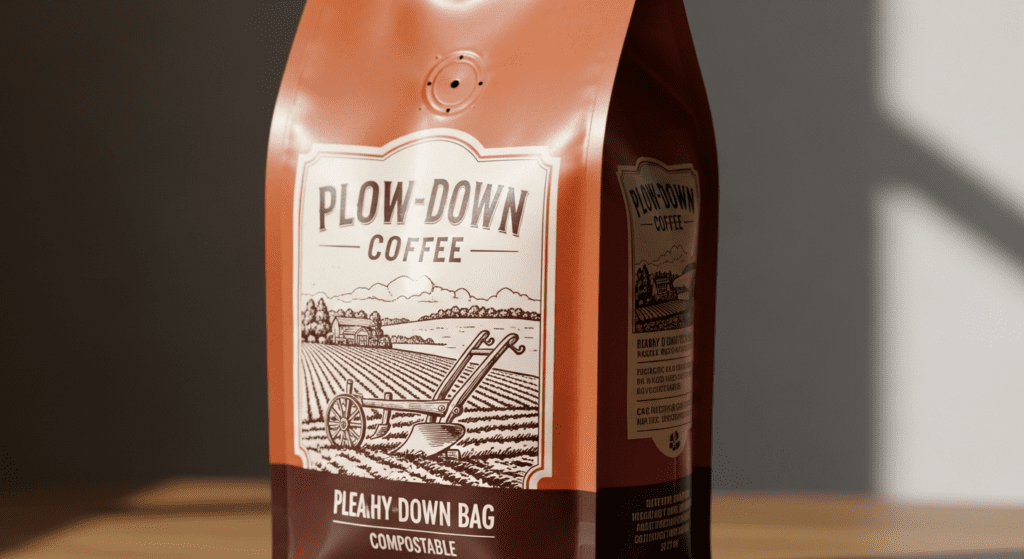

Plow-Down (Brick) Bag

Plow-down bags use mechanical devices to fold the top corners inward before sealing, creating a rectangular brick shape. This process transforms a standard pillow bag into a compact, stackable package.

The brick format maximizes shipping efficiency by eliminating wasted space between packages. Coffee producers often use this style for vacuum-packed ground coffee.

Plow-down attachments reduce bag volume by 20-30% compared to standard pillow bags. The compact shape also improves product freshness by minimizing air pockets within the package.