Sachet packaging machines are automated equipment designed to create small, sealed packets containing single servings of products. These machines help companies package everything from sugar and salt to shampoo samples and pharmaceutical powders into convenient, portion-controlled sachets.

What are Sachet Packaging Machines

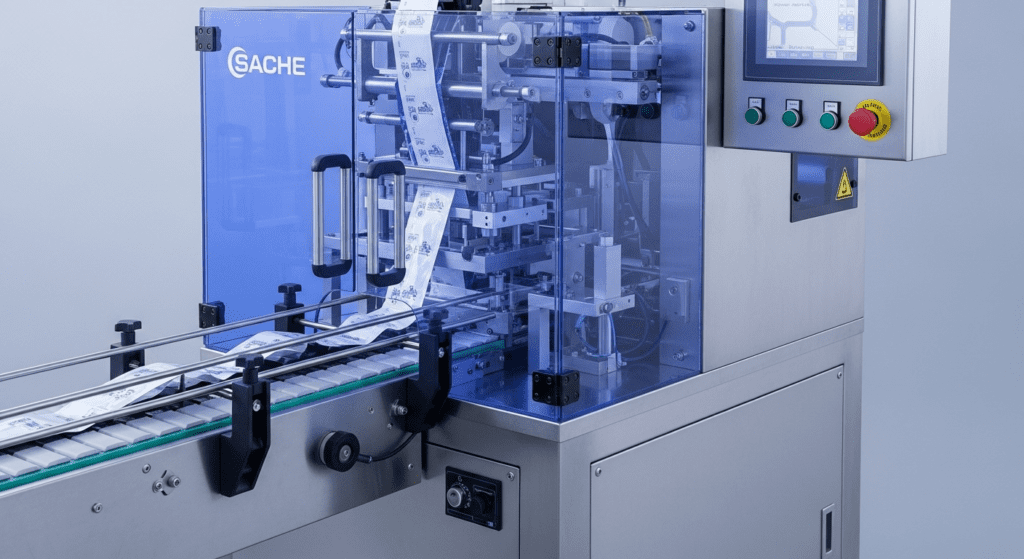

A sachet packaging machine forms, fills, and seals small packets that typically hold between 1-50 milliliters or grams of product. These machines work with flexible packaging materials like plastic films, aluminum foil, or paper laminates to create airtight pouches.

Think of sachets as the small packets you get with takeout food – ketchup, soy sauce, or sugar packets. But sachets go far beyond condiments. They’re used for cosmetics, medicines, instant coffee, spices, and even industrial chemicals.

How do Sachet Packaging Machines Work

I’ll walk you through the complete process of how sachet packaging machines work, breaking it down into clear steps. These machines are fascinating pieces of equipment that combine mechanical precision with automation to create those small, sealed packets you see for everything from ketchup to shampoo samples.

Step 1: Film Unwinding and Feeding

The process begins with a roll of packaging film, typically made of plastic, aluminum foil, or laminated materials. The film unwinds from a large roll mounted on the machine’s back.

Step 2: Sachet Formation

The flat film needs to be transformed into a pouch shape. The machine uses a forming collar or tube to wrap the film into a tubular shape.

The edges of the film overlap slightly, creating what we call a “back seal” or “longitudinal seal.” A heated sealing bar presses these overlapping edges together, creating a strong, airtight bond.

Step 3: Bottom Sealing

With the tube formed, the machine needs to create individual sachets. This starts with making the bottom seal. A pair of heated sealing jaws clamps across the tube horizontally, creating a seal that will become the bottom of one sachet and simultaneously the top of the previous one.

These jaws often have special patterns or textures that create those distinctive ridged seals you see on many sachets.

Step 4: Product Filling

Now comes the filling stage. Above the forming tube sits a dosing system tailored to the specific product.

- For liquids, this might be a piston filler that draws a precise amount from a hopper and pushes it through a nozzle.

- For powders, it could be an auger system (like a corkscrew) that measures by rotation, or a volumetric cup filler that scoops exact amounts.

The product drops through the center of the forming tube into the partially formed sachet. The filling happens while the bottom is sealed but the top remains open.

Step 5: Top Sealing and Cutting

Once the product is inside, the sealing jaws come together again, this time above the filled portion. This single operation accomplishes two things: it seals the top of the filled sachet and creates the bottom seal for the next sachet.

Simultaneously or immediately after, a cutting mechanism (usually a sharp blade integrated into the sealing jaw) cuts through the center of this seal, separating the completed sachet from the continuous tube.

Step 6: Quality Control and Rejection

Modern sachet machines include several quality control mechanisms.

- Weight checkers verify that each sachet contains the correct amount of product.

- Metal detectors scan for contamination.

- Vision systems check for proper sealing, correct printing, and overall appearance.

If a sachet fails any of these checks, an automatic rejection system removes it from the production line. This might be an air blast that blows the defective sachet into a separate bin, ensuring only perfect sachets continue to packaging.

Step 7: Collection and Secondary Packaging

The completed sachets fall into a collection system. Depending on the production requirements, they might drop into a large bin for bulk packaging, or feed directly into a cartoning machine that packs them into boxes. Some systems count sachets automatically and group them into specific quantities.

Types of Sachet Packaging Machines

The packaging industry offers several types of sachet machines, each designed for specific products and production needs.

Vertical Form-Fill-Seal (VFFS) Machines

VFFS machines create sachets from a roll of film that moves vertically through the machine. These are the most common type, making up about 60% of the sachet packaging market.

The film forms a tube around a vertical forming collar. Products drop down through this tube by gravity, which makes VFFS ideal for free-flowing powders and granules.

VFFS machines excel at packaging coffee, sugar, salt, and pharmaceutical powders. They produce 40-80 sachets per minute for single-lane models. Their vertical design saves floor space, making them perfect for facilities with limited room.

Horizontal Form-Fill-Seal (HFFS) Machines

HFFS machines move film horizontally through the packaging process. This orientation works better for liquids and products that don’t flow well vertically.

The horizontal design allows for gentler product handling. Delicate items like medical devices or products that need careful placement benefit from this approach.

HFFS machines often integrate with other packaging lines more easily. They’re commonly used for wet wipes, medical supplies, and liquid products that need precise positioning within the sachet.

Multi-Lane Sachet Machines

Multi-lane machines produce several sachets simultaneously from a single roll of film. A 4-lane machine can output 200-400 sachets per minute, dramatically increasing production capacity.

These machines work like multiple single-lane machines running in parallel. They’re ideal for high-volume production of small sachets, such as sugar packets for restaurants or sample-size cosmetics.

Premade Sachet Fillers

Unlike form-fill-seal machines, premade sachet fillers work with pouches that are already formed. Operators or automated systems load empty sachets into the machine, which then fills and seals them.

Premade sachet fillers typically run slower – about 20-40 sachets per minute. But they’re perfect for small batches, frequent product changes, or when you need exceptional sachet quality.

How to Choose the Right Sachet Packaging Machine

Selecting the ideal sachet packaging machine requires careful consideration of your specific needs and constraints. Here are the key factors to evaluate:

- Production Volume Requirements – Calculate how many sachets you need per hour, day, or month. A small business making 5,000 sachets daily needs different equipment than a factory producing 100,000. Single-lane machines handle up to 4,800 sachets per hour, while multi-lane systems can exceed 20,000.

- Product Characteristics – Your product type determines the filling system you need. Liquids require pumps or piston fillers with drip-prevention features. Free-flowing powders work with gravity or auger systems. Sticky products need special non-stick contact parts and stronger sealing systems.

- Sachet Size and Material – Measure your desired sachet dimensions and choose compatible film materials. Machines have minimum and maximum size limits – typically ranging from 30mm x 40mm up to 180mm x 300mm. Film thickness compatibility usually spans 30 to 120 microns.

- Budget Considerations – Entry-level machines start around $15,000, while high-speed multi-lane systems can exceed $200,000.

- Available Floor Space – Measure your production area carefully. VFFS machines need about 2-3 square meters of floor space plus height clearance of 2.5-3 meters. HFFS machines spread horizontally, requiring 3-5 meters in length but less height.

- Ease of Operation and Maintenance – Consider your team’s technical skills. Look for machines with intuitive touch-screen controls and clear maintenance schedules. Quick-change parts for different sachet sizes save hours of downtime. Local technical support availability can make or break your production schedule.

- Integration with Existing Systems – Your sachet machine should connect smoothly with upstream and downstream equipment. Check compatibility with your product feeders, check-weighers, and case packing systems.

- Regulatory Compliance – Food and pharmaceutical packaging requires specific certifications. Verify that machines meet FDA, CE, or other relevant standards for your market.