Impulse sealers are devices that use a short burst of electricity to heat a metal wire, which then melts and seals plastic packaging. They only heat during activation, making them energy-efficient. The sealing process takes 1–3 seconds and works well for polyethylene, polypropylene, and other thermoplastics.

What Are Impulse Sealers

Impulse sealers are machines that use short bursts of heat to seal plastic bags and packaging materials. These devices create airtight seals by melting plastic layers together using a heated wire or ribbon that only gets hot when you activate it.

Unlike constant heat sealers that stay hot all the time, impulse sealers only heat up for a few seconds during each seal. This makes them safer to use and more energy-efficient.

You’ll find impulse sealers in many places. Small businesses use them to package products. Hospitals seal medical supplies with them. Even home crafters use small models for their projects.

How do Impulse Sealers work

The impulse sealing process happens in four simple steps that take just 2-3 seconds total.

First, you place the plastic material between the sealing bars and press down to close them.

When you activate the sealer (by pressing down or pushing a button), electricity flows through a thin heating wire inside the sealing bar. This wire heats up to 300-500°F in less than a second.

The hot wire melts the plastic layers together while pressure from the sealing bars holds them in place. After 1-2 seconds, the electricity stops and the wire starts cooling down.

The sealing bars stay closed for another second or two while the melted plastic cools and hardens. This cooling time ensures you get a strong, permanent seal.

Once complete, you open the bars and remove your sealed package. The whole process creates a neat, straight seal line that’s usually 2-5mm wide.

Types of Impulse Sealers

Impulse sealers come in three main types, each designed for different workloads and applications.

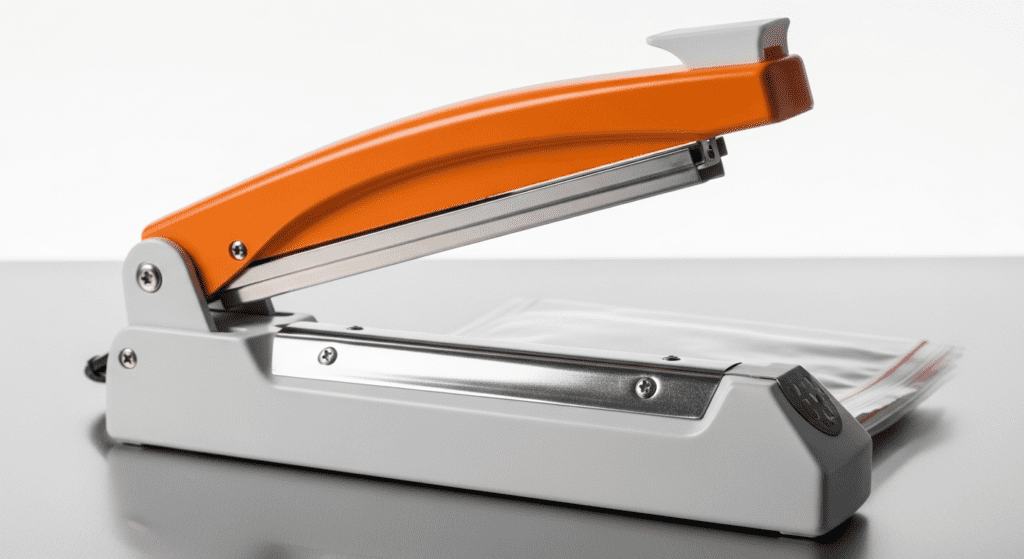

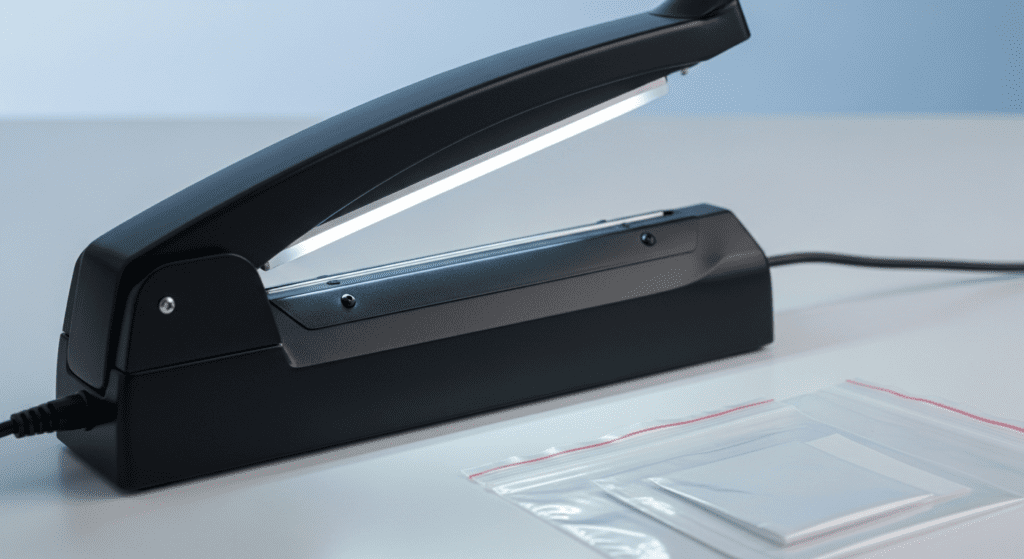

Manual (Tabletop) Sealers

Manual impulse sealers are the most common type you’ll see in small businesses and shops. These compact units sit on a table or counter and require you to press down on a handle to create each seal.

Most manual sealers can seal bags up to 8-20 inches wide. They typically cost between $30-$300 depending on size and features.

These sealers work great when you’re sealing less than 100 bags per day. They’re perfect for small retail stores, craft businesses, or home use.

Foot-Operated Sealers

Foot-operated sealers free up both your hands to position bags perfectly before sealing. You press a foot pedal to activate the sealing mechanism while your hands hold the material in place.

These units can handle 200-500 seals per day comfortably. They usually seal bags from 12-35 inches wide and cost between $200-$1,000.

Many packaging departments prefer foot sealers because workers can seal faster and more accurately. The hands-free operation also reduces fatigue during long packaging sessions.

Automatic Sealers

Automatic impulse sealers use sensors and timers to seal bags without any manual activation. You simply insert the bag, and the machine does the rest.

These machines can seal 1,000+ bags per day with consistent quality. They often include features like adjustable seal time, temperature controls, and conveyor systems.

Automatic sealers start around $1,500 and can cost over $10,000 for industrial models. Large warehouses and manufacturing plants use these when they need maximum speed and efficiency.

Impulse Sealer Parts

Each impulse sealer contains five main components that work together to create perfect seals.

The Sealing Jaw Assembly and Pressure System

The sealing jaws are the metal bars that press together to hold your plastic in place. Spring-loaded mechanisms or pneumatic systems provide 20-60 pounds of pressure to ensure good contact between plastic layers.

The Heating Element

A thin nichrome wire (usually 0.5-2mm thick) runs along the sealing bar. This special wire heats up quickly when electricity passes through it and cools down fast when power stops.

The Protective Barrier System

Teflon tape or silicone rubber covers the heating wire to prevent plastic from sticking. This barrier needs replacing every 1,000-5,000 seals to maintain seal quality.

The Counter-Jaw

The bottom jaw provides a firm, flat surface for the heating element to press against. Made from silicone rubber or similar heat-resistant material, it ensures even pressure across the entire seal width.

The Control System

A timer circuit controls how long electricity flows to the heating element. Most sealers let you adjust this time from 0.1 to 3 seconds to match different plastic thicknesses.

Materials Suitable for Impulse Sealing

Impulse sealers work with many types of plastic films, but some seal better than others. The key is using thermoplastic materials – plastics that melt when heated and harden when cooled.

Polyolefins

Polyolefins are the most common plastics used with impulse sealers. They seal easily and create strong, reliable bonds.

- Polyethylene (PE): PE is the most popular packaging plastic worldwide. Low-density PE seals at 250-300°F, while high-density PE needs 275-325°F. You’ll find PE in grocery bags, bubble wrap, and shrink film.

- Polypropylene (PP): PP requires higher temperatures (300-350°F) but creates very strong seals. It’s commonly used for food packaging, medical supplies, and products that need moisture barriers.

Other Common Plastics

Several other plastics work well with impulse sealers, though they may need specific temperature settings.

- Polyvinyl Chloride (PVC): PVC seals at 275-325°F and creates clear, strong seals. It’s often used for retail packaging and protective covers.

- Polyurethane: This flexible plastic seals at 300-400°F. Medical device manufacturers often use polyurethane for sterile packaging.

- Nylon (Polyamide): Nylon needs higher temperatures (350-425°F) but provides excellent strength. It’s ideal for vacuum packaging and heavy-duty applications.

- Polyester (PET): PET requires 400-480°F to seal properly. While challenging to seal, it offers superior clarity and strength for premium packaging.

- Polystyrene (PS): PS seals at relatively low temperatures (225-275°F). It’s commonly found in foam packaging and disposable containers.

Specialty Films and Laminates

Modern packaging often uses multi-layer materials that combine different plastics for better performance.

- Bubble packs and padded mailers: These materials have PE or PP outer layers that seal normally. The bubble layer inside doesn’t affect sealing as long as the outer layers make good contact.

- Coextruded films (COEX): COEX films combine 2-7 layers of different plastics. The sealing layer (usually PE or PP) determines the temperature needed. These films offer benefits like oxygen barriers or enhanced strength while still sealing easily.

What Is the Difference Between Impulse Sealing and Constant (Direct) Heat Sealing

The main difference between impulse sealing and constant (direct) heat sealing is the heating method. Impulse sealers heat the element only during sealing, reducing energy use and making them safer. Constant heat sealers maintain continuous heat, enabling faster, thicker, or specialty material sealing.

How Long Does a Vacuum Sealer Last

A vacuum sealer lasts between 3 to 10 years depending on brand, usage frequency, and maintenance. Light household use typically results in 5 years of service, while commercial-grade sealers can exceed 10 years with proper care.

Learn more about What Is the Difference Between Vacuum Sealer and Impulse Sealer