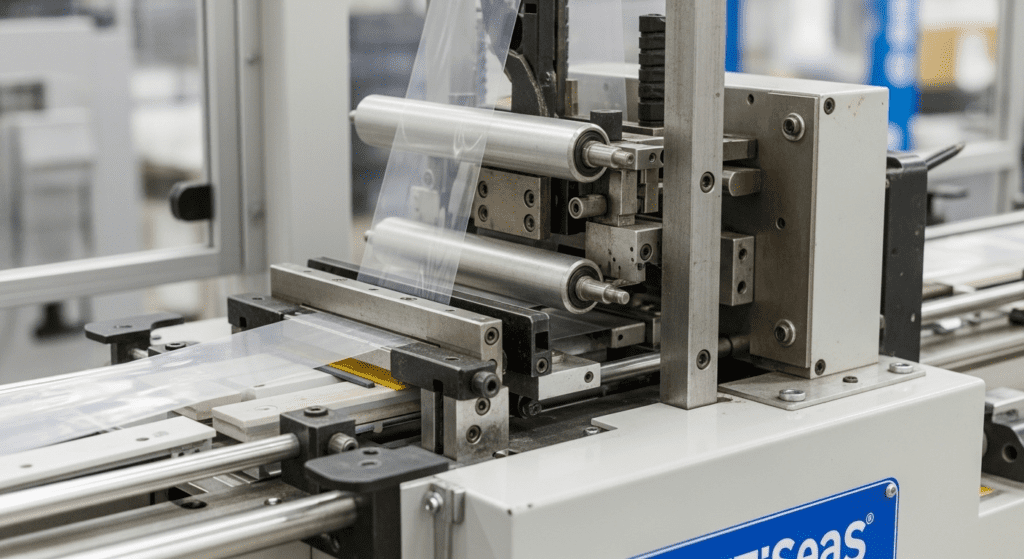

VFFS machines are the workhorses of modern packaging lines. But like any complex equipment, they can develop problems that slow down production or damage product quality.

This guide covers the most common VFFS issues and their solutions. Whether you’re dealing with film tracking problems or seal failures, you’ll find practical fixes here.

Film Feed and Tracking Issues

Film feed problems are the most frequent issues operators face. When the film doesn’t move correctly through the machine, it creates a domino effect of other problems down the line.

Film drifting/misalignment

Film drift happens when the material gradually moves off-center as it travels through the machine. The main cause is uneven tension across the film width.

Check your film roll first. It should be perfectly centered on the unwind shaft. Even a quarter-inch offset can cause major tracking issues.

Adjust the edge guide sensors to maintain proper positioning. These sensors should be clean and positioned about 1/8 inch from the film edge.

Film not tracking (jittering or wandering)

Jittering film creates inconsistent bag quality and can damage the material. This usually stems from worn or dirty rollers.

Inspect all idler rollers for buildup of adhesive or product residue. Clean them with isopropyl alcohol and a lint-free cloth.

Check bearing condition in all rollers. A single bad bearing can cause the entire web to wander unpredictably.

Film tension problems

Proper tension is critical for good bag formation. Too much tension stretches the film thin. Too little causes wrinkles and poor seals.

Set your dancer arm to the middle position when the machine is at rest. During operation, it should move smoothly without hitting its travel limits.

Brake tension should be just enough to prevent the film roll from coasting when the machine stops. Start with minimal brake pressure and increase gradually.

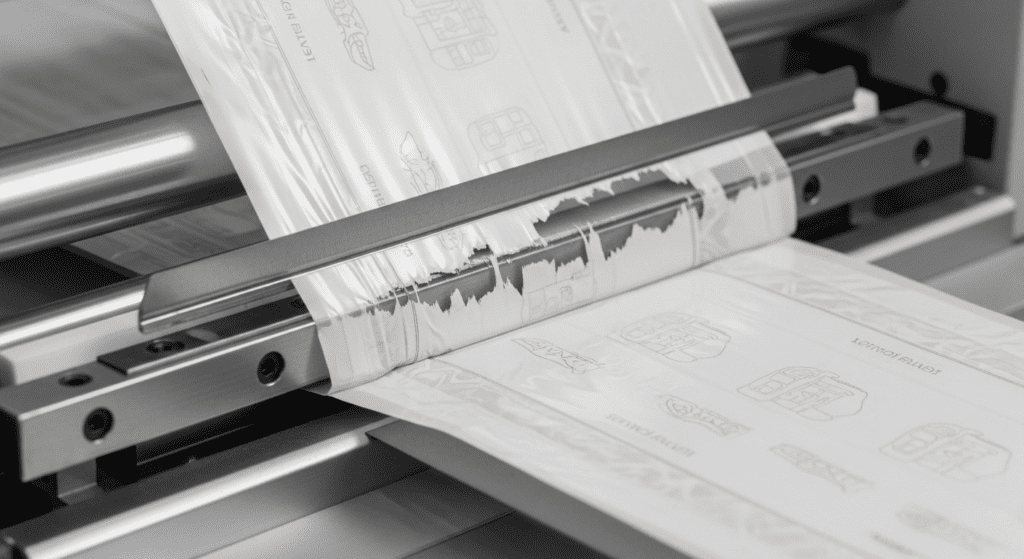

Eye-mark or registration errors

Registration marks ensure each bag is cut in the right place. When the sensor can’t read these marks, bags come out with misplaced graphics.

Clean the photo-eye lens daily. Even a thin film of dust can prevent proper mark detection.

Verify the sensor’s sensitivity setting matches your film type. Clear films need different settings than metalized materials.

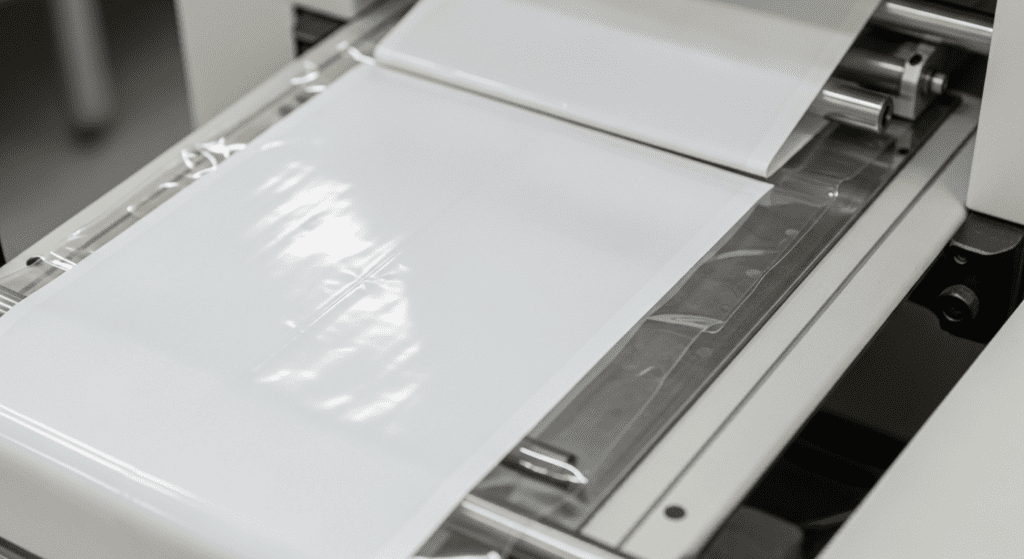

Bag Forming Issues

The forming collar shapes flat film into a tube. Problems here affect every bag your machine produces.

Wrinkles or creases on bags

Wrinkles usually appear when the film doesn’t lay flat against the forming collar. Temperature and alignment are the usual culprits.

Check that your forming collar matches the bag width exactly. A collar that’s too wide or narrow will create diagonal wrinkles.

Verify the collar is perfectly vertical using a level. Even a 2-degree tilt can cause persistent creasing.

Misshapen or skewed bags

Skewed bags indicate the film isn’t feeding straight into the forming section. This often traces back to the unwind section.

Ensure the film unwind shaft is parallel to the forming collar. Use a tape measure to check distances at multiple points.

Inspect the forming collar for damage or product buildup. Even minor scratches can catch the film edge and pull it off-center.

Inconsistent bag length

Variable bag lengths waste material and confuse downstream equipment. The root cause is usually encoder or pull belt issues.

Clean the encoder wheel and verify it maintains constant contact with the film. Any slipping will throw off length calculations.

Check pull belt tension. The belts should grip firmly without crushing the film. Replace worn belts that show glazing or cracks.

Gusset or tuck problems

Gusseted bags require precise tucker blade timing. Misalignment here creates bags that won’t stand properly.

Adjust tucker blades so they engage the film just as it enters the forming collar. Early engagement tears film. Late engagement creates incomplete gussets.

Verify tucker blade springs provide consistent pressure. Weak springs create shallow, unstable gussets.

Sealing Issues

Good seals are essential for product protection. Seal problems lead to leaks, contamination, and customer complaints.

Vertical (fin) seal failures

The vertical seal runs the entire bag length. When it fails, the whole bag opens up.

Check seal bar temperature first. Most films seal between 250-350°F, but verify your specific material’s requirements.

Inspect seal bar surfaces for pitting or product buildup. Even microscopic contamination prevents proper film bonding.

Horizontal (end) seal failures

End seals close the top and bottom of each bag. These high-stress areas need perfect execution.

Verify seal jaw alignment using carbon paper. The impression should be even across the entire seal width.

Check seal dwell time. Quick seals don’t allow proper heat transfer. Excessive dwell time burns through the film.

Overheating/Underheating seals

Temperature control is critical for consistent seals. Problems here show up as burnt film or weak bonds.

Calibrate temperature controllers monthly using an external thermocouple. Controllers can drift over time.

Inspect heating elements for hot spots or dead zones. Replace any elements showing discoloration or physical damage.

Leaking seals/Contamination

Product in the seal area is the number one cause of leakers. This requires timing adjustments or product control improvements.

Adjust fill timing so product flow stops before seal jaws close. Add a settling delay if necessary for dusty products.

Install air knives above seal areas to blow away contaminating particles. This is especially important for powdery products.

Filling Issues

Accurate fills satisfy customers and meet regulatory requirements. Fill problems waste product and create legal liability.

Underfill/Overfill

Fill weight accuracy depends on proper calibration and consistent product flow. Both mechanical and control issues can cause problems.

Calibrate your scale or volumetric filler weekly. Use certified check weights for best accuracy.

Verify product density hasn’t changed. Seasonal humidity variations can significantly affect powder weights.

Inconsistent fills

Random fill variations usually indicate mechanical problems in the filling system.

Check auger flights or volumetric cups for wear. Even minor damage creates significant volume changes.

Inspect product hopper for bridging or rat-holing. Install vibrators or agitators if necessary for difficult products.

Timing errors (product in seals)

Product contamination in seal areas creates weak seals and messy packages. This is primarily a timing issue.

Adjust the fill cutoff to stop product flow 0.5 seconds before seal jaw closure. Fine-tune based on your product’s flow characteristics.

Verify the fill tube ends above the seal area. Extension tubes may be needed for free-flowing products.

Tuck or transition fill

Some applications use tuck filling to minimize seal contamination. This requires precise coordination between filling and forming.

Set tuck timing so product enters the bag just as the previous seal cools. Too early creates buildup. Too late causes underfills.

Monitor tuck blade wear. Damaged blades create inconsistent tucks and product placement.

Cutting Issues

Clean cuts are essential for professional-looking packages and proper downstream handling.

Incomplete or ragged cuts

Dull or damaged knives create ugly, dangerous bag edges. Regular maintenance prevents most cutting problems.

Replace knives at the first sign of dulling. Don’t wait for obvious problems to develop.

Verify knife-to-anvil clearance is within specification. Too much gap leaves uncut fibers. Too little damages both components.

Cut timing/misalignment

Cuts must occur at exactly the right position for proper bag appearance and function.

Check encoder feedback for consistency. Erratic signals create random cut positions.

Verify mechanical linkages have no play or wear. Even small amounts of backlash accumulate into major positioning errors.

Film tension effects on cutting

Incorrect tension makes clean cutting impossible. The film must be taut but not stretched.

Set film tension just high enough to eliminate wrinkles. Excessive tension causes film necking and weak cuts.

Monitor dancer arm position during cutting. It should remain steady without sudden movements.

Foreign material

Contamination on cutting surfaces creates incomplete cuts and can damage knives.

Clean knife and anvil surfaces every shift. Use appropriate solvents for your product type.

Install guards or air curtains to prevent product migration to cutting areas.

Machine Controls and Sensors

Modern VFFS machines rely on sophisticated controls. When these fail, the entire operation stops.

PLC/HMI faults

Control system problems require systematic troubleshooting. Start with the basics before assuming component failure.

Check all cable connections first. Vibration can loosen even properly installed connectors.

Verify proper grounding throughout the system. Poor grounds cause erratic behavior and false faults.

Sensor errors

Sensors provide the feedback necessary for automatic operation. Failed sensors create unpredictable machine behavior.

Test each sensor individually using the manual mode. This isolates problems without risking product waste.

Clean all photo-eyes and proximity sensors daily. Environmental contamination is the leading cause of sensor failures.

Encoder/Scale

Precision feedback devices require careful handling and maintenance. Small errors here create big problems.

Verify encoder mounting is secure without excessive runout. Mechanical play creates inconsistent signals.

Calibrate scales using certified weights across the entire operating range. Don’t rely on single-point calibration.

Electrical issues

Power quality affects every aspect of machine operation. Poor power creates mysterious, intermittent problems.

Install power monitoring to detect voltage sags and spikes. Many “random” problems trace back to power issues.

Check all ground connections annually. Corrosion creates high-resistance paths that compromise machine operation.

Control settings

Incorrect parameters cause consistent problems that operators often work around instead of fixing.

Document all control settings when the machine runs well. This provides a baseline for troubleshooting.

Train operators on the effects of each setting. Understanding prevents random “knob turning” that creates new problems.

Air Pressure and Pneumatics

Compressed air powers many VFFS functions. Pressure problems affect sealing, cutting, and product handling.

Low air pressure

Insufficient pressure creates weak, inconsistent machine movements. This shows up as seal failures and timing problems.

Verify main air supply delivers consistent pressure above machine requirements. Install larger supply lines if necessary.

Check for leaks throughout the pneumatic system. Even small leaks compound into major pressure drops.

Cylinder or clamp failures

Pneumatic cylinders provide the force for sealing and cutting. Worn cylinders create quality problems.

Monitor cylinder speed and force. Slow or weak movements indicate internal wear or seal damage.

Replace cylinders showing any external leakage. Don’t wait for complete failure.

Pressure imbalance

Different machine functions require different pressures. Imbalances create timing and quality issues.

Install individual regulators for each machine section. This allows optimization without compromise.

Verify regulator settings monthly. Vibration can cause drift in mechanical regulators.

Vacuum or ejector issues

Many machines use vacuum for film handling or product transfer. Loss of vacuum creates immediate problems.

Clean vacuum filters daily. Clogged filters dramatically reduce available vacuum.

Check vacuum generator efficiency. Worn generators consume excess air while providing inadequate vacuum.

Product Compatibility Issues

Different products create unique challenges. Understanding these helps prevent problems before they occur.

Dusty or powdery products

Fine powders infiltrate everywhere, causing seal contamination and mechanical wear.

Install effective dust collection at all open points. This protects both product quality and machine components.

Use film with good static-dissipative properties. Static attracts dust to seal areas.

Sticky or oily products

Adhesive products build up on machine surfaces, creating cleaning nightmares and quality problems.

Select film with appropriate release characteristics. Some coatings prevent product adhesion.

Schedule frequent cleaning for product contact areas. Don’t let buildup accumulate.

Foaming liquids

Foamy products create special filling challenges. Standard techniques often fail completely.

Use bottom-up filling when possible. This minimizes foam generation during filling.

Add defoaming agents if product specifications allow. Even small amounts dramatically improve filling.

Free-flow vs. bridging products

Product flow characteristics determine optimal machine setup. What works for sugar fails for flour.

Install appropriate agitation for bridging products. Gentle vibration often solves flow problems.

Adjust fill tube diameter based on product characteristics. Larger tubes help bridging products.

Temperature/humidity sensitivity

Environmental conditions affect both product and film properties. Control these variables for consistent operation.

Monitor temperature and humidity near the machine. Install conditioning equipment if variations exceed acceptable limits.

Adjust machine parameters seasonally. What works in winter may fail during humid summers.