Sealing machines create airtight or watertight closures on packages, bags, bottles, and containers. These machines work by using heat, vacuum, electromagnetic fields, or sound waves to bond materials together or create protective seals.

There are four main categories of sealing machines: heat sealing, vacuum sealing, induction sealing, and ultrasonic sealing. Each type serves different packaging needs and works with specific materials.

Heat Sealing Machines

Heat sealing machines use temperature to melt and fuse thermoplastic materials together. They’re the most common type of sealing equipment found in packaging operations.

These machines work by applying controlled heat to create permanent bonds between plastic films, bags, or pouches. The heat melts the material surfaces just enough to fuse them when pressed together.

Heat sealing comes in several varieties, each designed for different packaging speeds and material types. Let’s explore the four main types of heat sealers you’ll encounter.

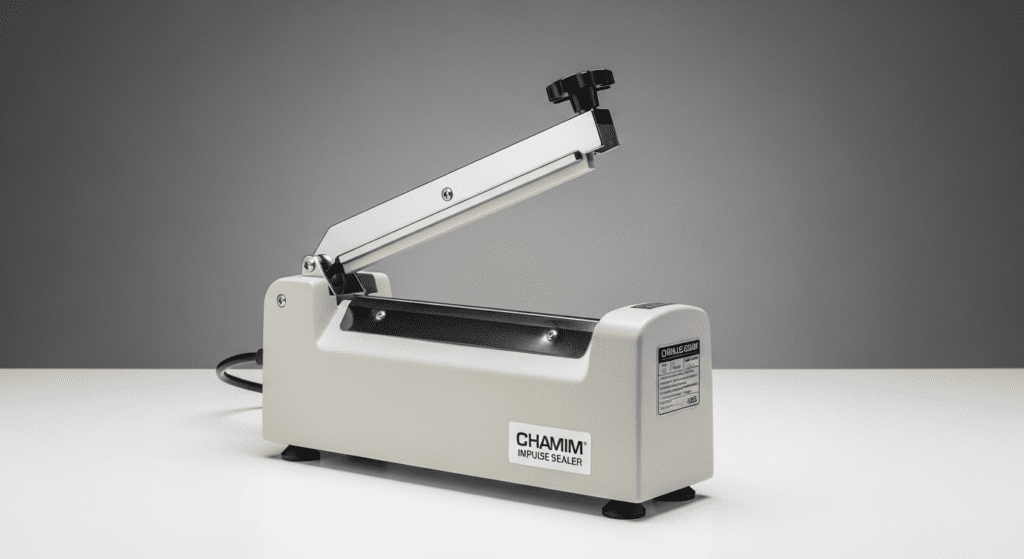

Impulse Sealer

Impulse sealers heat up only when you activate them, typically lasting 0.2 to 2 seconds per seal. They use a thin heating wire that quickly reaches temperatures between 300-500°F when electricity flows through it.

These sealers work best for thin plastic materials up to 10 mil thickness. The heating element cools down immediately after each seal, which prevents the plastic from sticking to the sealing bar.

You’ll find impulse sealers in small businesses, retail stores, and light manufacturing. They’re perfect for sealing poly bags, cellophane, and lightweight plastic pouches at rates of 5-20 packages per minute.

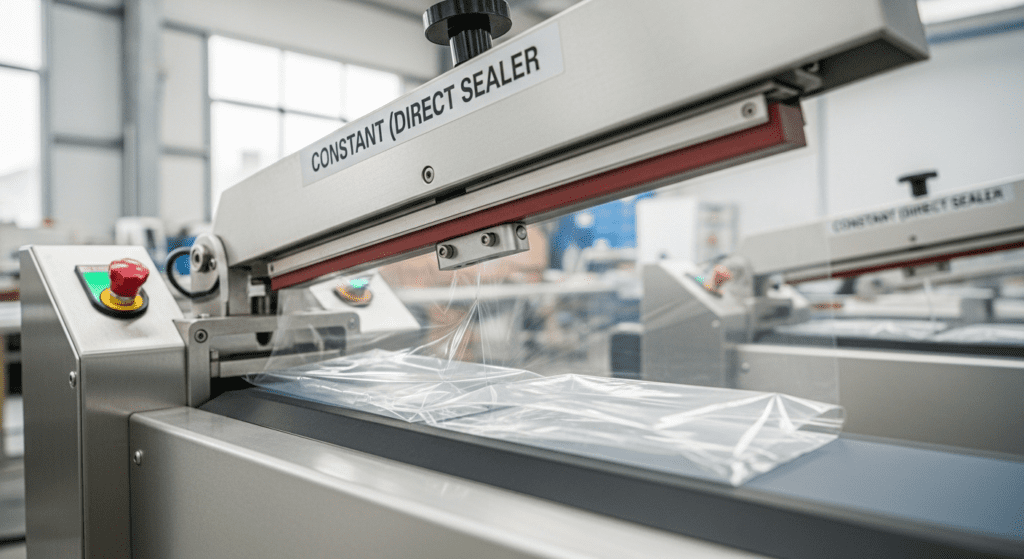

Constant (Direct) Heat Sealer

Constant heat sealers maintain a steady temperature throughout operation, usually between 250-450°F. The heating elements stay hot continuously, allowing for faster sealing speeds than impulse models.

These machines handle thicker materials up to 15 mil and work well with gusseted bags, heavy-duty plastics, and coated papers. They create stronger seals because the constant heat penetrates deeper into the material.

Direct heat sealers suit medium to high-volume operations that need to seal 20-60 packages per minute. Food manufacturers, medical supply companies, and industrial packagers commonly use these machines.

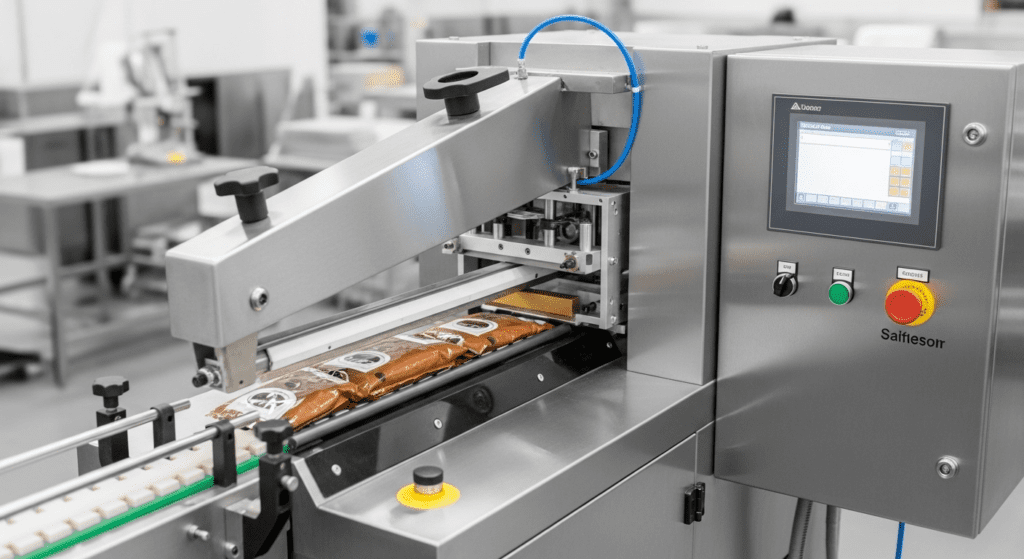

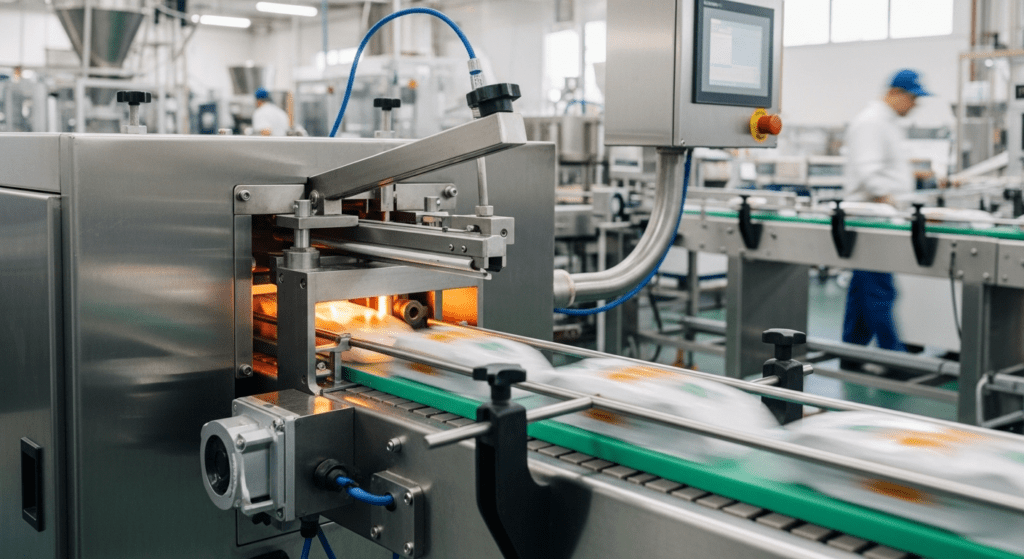

Continuous Band Sealer

Continuous band sealers move packages through the machine on a conveyor belt while sealing them. They can process 30-120 feet of sealed material per minute, depending on the model.

These machines use heated bands or belts that apply consistent pressure and temperature as products pass through. Most models include cooling zones that solidify the seal before packages exit the machine.

Band sealers excel at high-volume operations where speed matters. They’re ideal for sealing stand-up pouches, large bags of pet food, or any package that needs horizontal or vertical sealing on a production line.

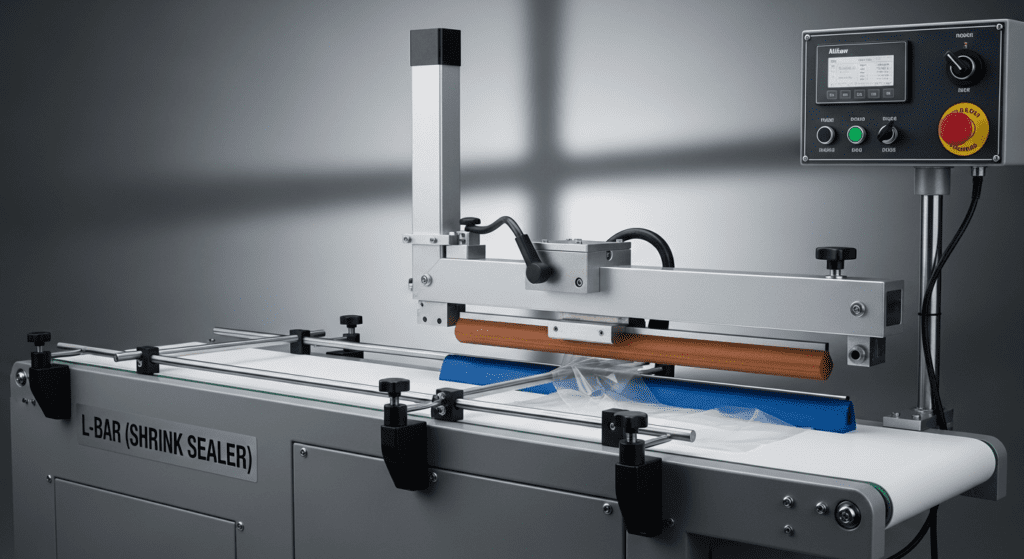

L-Bar (Shrink) Sealer

L-bar sealers create two perpendicular seals in one motion, forming an “L” shape. They work with shrink film to completely enclose products before the film shrinks tight in a heat tunnel.

These machines cut and seal film around products in 2-5 seconds per cycle. The sealing wire reaches 350-500°F to simultaneously cut excess film and create clean, professional-looking seals.

L-bar sealers package everything from books and DVDs to gift baskets and retail products. They produce 5-15 packages per minute and create the clear, tight wrapping you see on many consumer goods.

Vacuum Sealing Machines

Vacuum sealing machines remove air from packages before sealing them shut. This process extends shelf life by preventing oxidation and reducing bacterial growth.

These machines pull out 99.8% of air from packages, creating an oxygen-free environment. Food stays fresh 3-5 times longer when vacuum sealed compared to conventional storage methods.

Vacuum sealers come in two main designs that suit different packaging needs and production volumes.

Chamber Vacuum Sealer

Chamber vacuum sealers place the entire package inside a sealed chamber during operation. The machine removes air from both the chamber and the package simultaneously, creating equal pressure inside and outside the bag.

These sealers achieve vacuum levels of 0.5-5 millibar and work with liquids without sucking them out of the package. The equal pressure prevents liquids from boiling or getting pulled into the vacuum pump.

Commercial kitchens, meat processors, and food manufacturers rely on chamber sealers. They handle 2-8 cycles per minute and work with special vacuum bags that cost $0.05-0.15 each.

External Vacuum Sealer

External vacuum sealers keep products outside the machine while removing air through the bag opening. They’re smaller, more affordable, and easier to operate than chamber models.

These machines achieve vacuum levels of 20-50 millibar and work best with solid foods and dry goods. They struggle with liquids because the suction can pull moisture into the sealing area.

Home users and small businesses prefer external sealers for their convenience and $50-500 price range. They process 10-40 inches of seal per minute and use textured bags that allow air removal.

Induction Sealing Machines

Induction sealing machines use electromagnetic fields to create tamper-evident seals on bottles and jars. They heat aluminum foil liners inside cap liners without touching the container.

The process works by generating a magnetic field that causes eddy currents in the foil. These currents heat the foil to 250-350°F in 0.5-3 seconds, melting a polymer layer that bonds to the container rim.

Induction sealing provides the best protection against leaks, contamination, and tampering. Let’s examine the three main types of induction sealers.

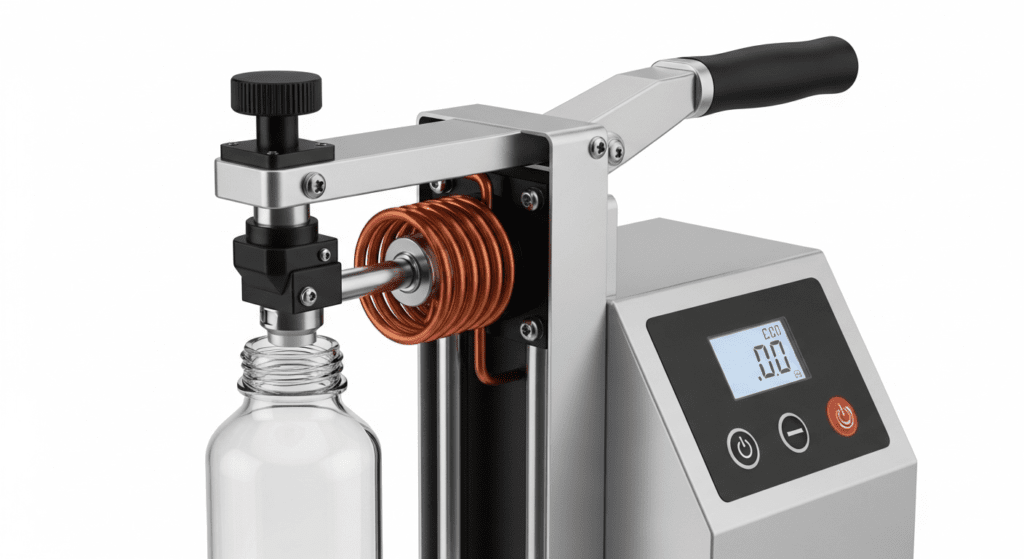

Portable / Manual Induction Sealers

Portable induction sealers operate like handheld tools that operators place over each cap. They generate 500-1500 watts of power and seal containers one at a time.

These sealers work for containers from 10mm to 120mm in diameter. Operators hold the sealing head over each cap for 1-3 seconds to create a perfect seal.

Small producers, laboratories, and businesses sealing fewer than 500 containers daily choose portable sealers. They cost $1,500-5,000 and require minimal setup or maintenance.

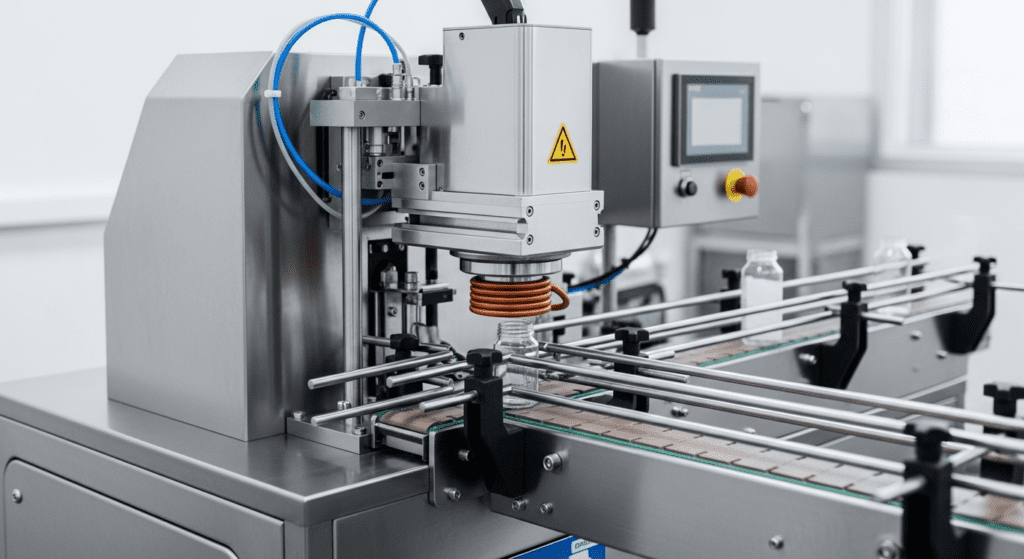

Inline (Continuous) Induction Sealers

Inline induction sealers mount above conveyor systems to seal containers as they pass underneath. They generate 2-12 kilowatts of power and handle 20-600 containers per minute.

These systems automatically adjust power levels based on conveyor speed and cap size. The sealing tunnel extends 6-24 inches to ensure complete seals even at high speeds.

Pharmaceutical companies, food manufacturers, and chemical producers install inline sealers on production lines. They integrate with existing equipment and provide consistent, reliable seals.

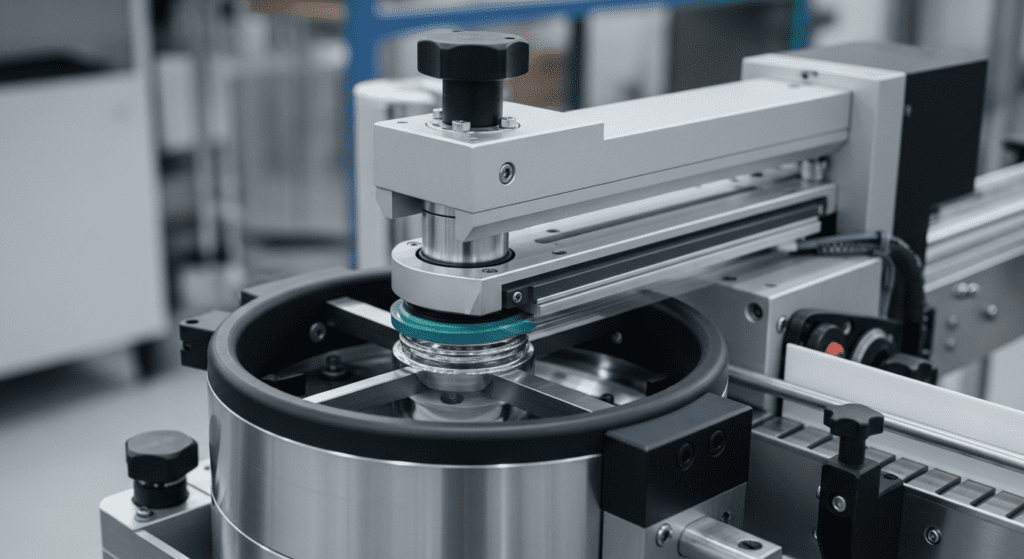

Rotary / Capless Sealers

Rotary induction sealers work with specialized capping machines in high-speed operations. They seal containers immediately after capping while bottles rotate through the machine.

These sealers handle round containers at speeds up to 1,200 units per minute. The rotating motion ensures even heat distribution and prevents hot spots that could damage products.

Beverage bottlers, dairy processors, and large-scale manufacturers use rotary sealers. They’re essential for operations that need maximum speed without sacrificing seal quality.

Ultrasonic Sealing Machines

Ultrasonic sealing machines use high-frequency sound waves to create molecular friction that melts and bonds materials. They operate at 20-40 kilohertz, beyond human hearing range.

These machines convert electrical energy into mechanical vibrations through a transducer. The vibrations travel through a metal tool called a horn, which presses against the materials being sealed.

Ultrasonic sealing works without adding heat from outside sources. The friction between vibrating material layers generates temperatures of 180-500°F precisely where needed.

This technology excels at sealing synthetic fabrics, thin films, and non-woven materials. It creates strong, consistent seals in 0.1-1 second without adhesives or added materials.

Medical device manufacturers use ultrasonic sealing for sterile packaging and surgical gowns. Food companies seal powder packets and tea bags with this clean, efficient method.