Packaging machinery helps businesses pack products quickly and efficiently. From small bottles to large pallets, these machines handle every step of the packaging process.

Let’s explore the main types of packaging equipment you’ll find in today’s factories and warehouses.

Filling Machines

Filling machines put products into containers with precise measurements. They work with liquids, powders, and solid items, making sure each package has the right amount.

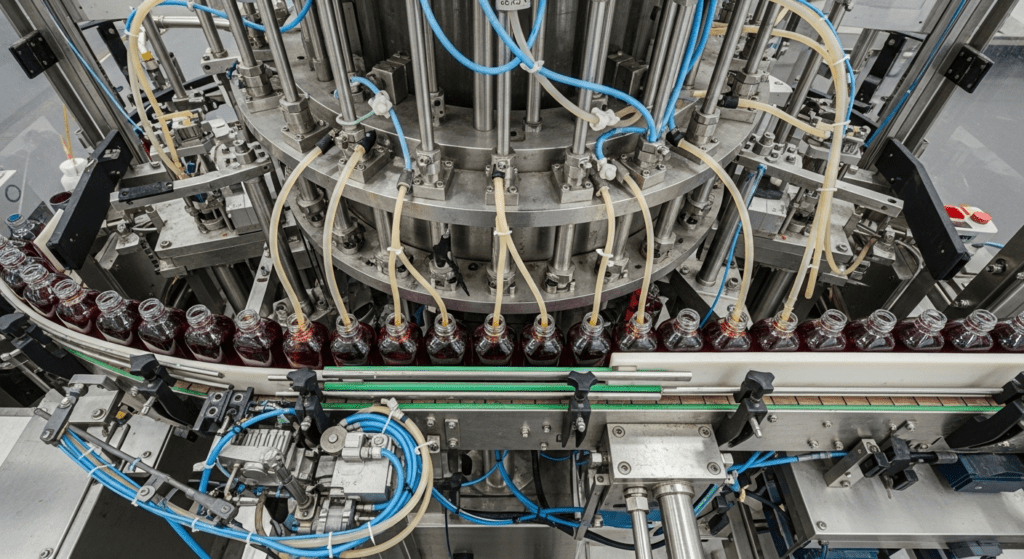

Liquid fillers

Liquid fillers pour liquids like water, juice, or shampoo into bottles and containers. They work in three main ways.

- Gravity fillers let liquid flow down into containers using weight alone.

- Piston fillers use a cylinder to push exact amounts of product.

- Pump-type fillers move liquids through tubes and valves for consistent filling.

Powder/Auger fillers

Powder fillers use a spinning screw (called an auger) to move dry products. They work great for flour, spices, and powdered drinks.

The auger turns at a set speed to deliver precise amounts every time.

Pouch/bag fillers

These machines fill flexible packages like stand-up pouches and bags. They can handle both liquids and solids.

These machines can fill stand-up pouches, flat bags, and even zip-lock style bags. Many snack foods and pet foods use pouch fillers.

Volumetric/Net-weigh fillers

Volumetric fillers measure products by volume (how much space they take up). Net-weigh fillers measure by weight.

Volumetric fillers work fast but might have small differences in weight. Net-weigh fillers are more accurate but usually work a bit slower.

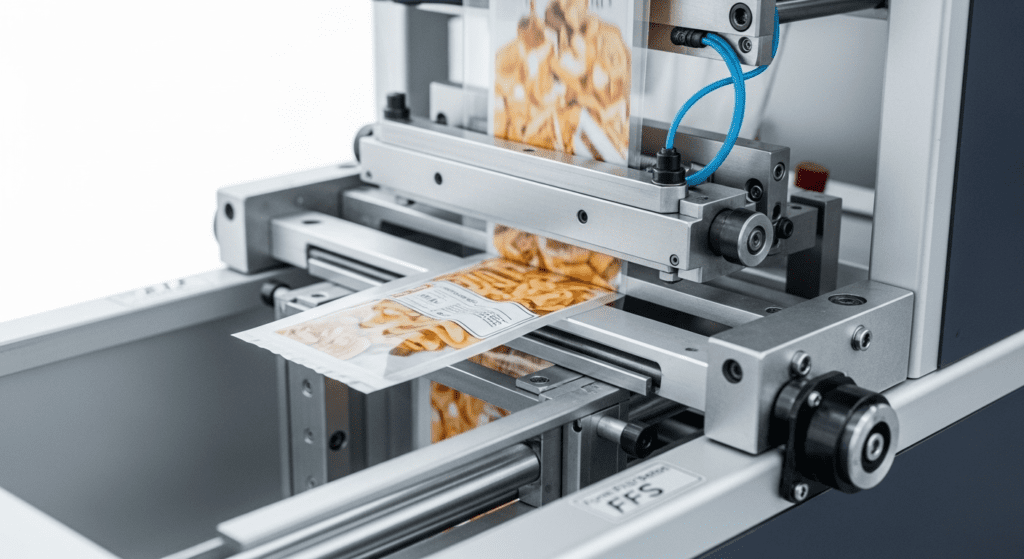

Form-Fill-Seal (FFS) Machines

Form-Fill-Seal machines do three jobs in one. They form a package from flat material, fill it with product, and seal it closed. These machines save space and time by doing everything in one spot.

Vertical Form-Fill-Seal (VFFS)

VFFS machines make bags from a roll of film while the film hangs vertically. The machine forms the film into a tube, fills it from the top, and seals both ends.

You see VFFS packages everywhere – potato chips, frozen vegetables, and coffee all use this type of packaging. These machines can make 30 to 300 bags per minute.

Horizontal Flow Wrappers (HFFS)

HFFS machines wrap products moving sideways along a conveyor. The film wraps around the product and seals on the bottom or back.

You’ll see these wrapping candy bars, cookies, and medical supplies. They can handle up to 1,500 products per minute.

Sealing Machines

Sealing machines close packages to keep products fresh and secure. Different types of sealers work with various materials and create different seal strengths.

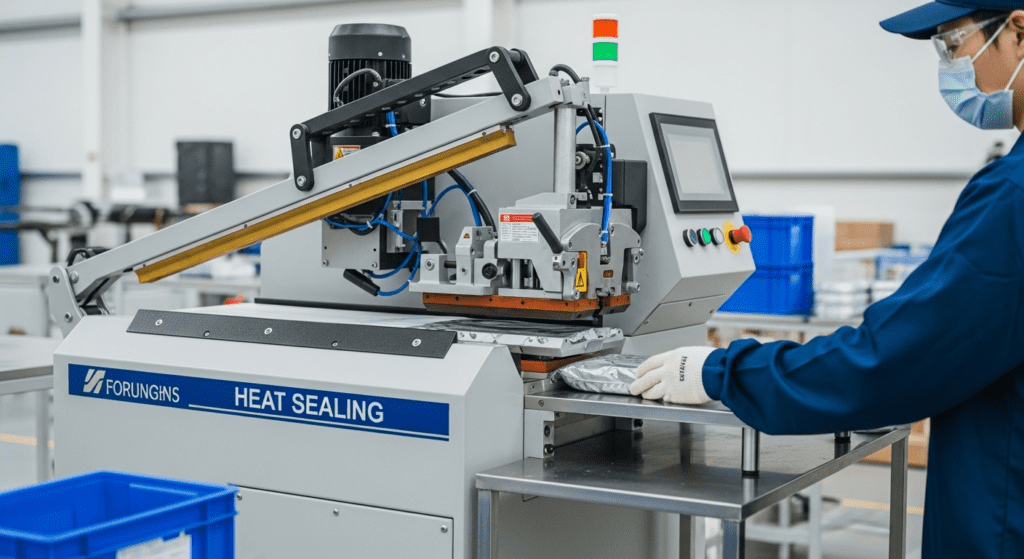

Heat Sealers

Heat sealers use hot metal bars or wires to melt plastic together. They press heated bars against the package edges to create a strong seal.

The temperature usually ranges from 250 to 400 degrees Fahrenheit. Seal time takes just 1-3 seconds.

Induction Sealers

Induction sealers create tamper-evident seals on bottles and jars. They use electromagnetic fields to heat aluminum foil liners.

These machines seal containers without touching them. This keeps the process clean and fast.

Vacuum Sealers

Vacuum sealers remove air from packages before sealing them. Taking out the air helps food last longer and prevents freezer burn.

Many meat products and cheese use vacuum sealing. Industrial vacuum sealers can process 2 to 60 packages per minute, depending on the package size.

Labeling Machines

Labeling machines put important information on packages. They apply labels with product names, barcodes, expiration dates, and more.

Pressure-sensitive labelers

These machines stick pre-printed labels onto products. The labels have adhesive backing that sticks when pressed.

They can apply 20 to 300 labels per minute. Most work with round, square, or oval containers.

Sleeve labelers

Sleeve labelers slide plastic sleeves over containers. Heat or steam then shrinks the sleeve to fit tightly.

These labels cover the entire container surface. They’re popular for beverages and personal care products.

Wrap-around labelers

Wrap-around labelers use glue to attach paper or plastic labels. The label wraps completely around the container.

These machines handle up to 1,000 containers per minute. They work great for cans and bottles.

Wrapping Machines

Wrapping machines protect products during shipping and storage. They use various materials to secure items on pallets or in bundles.

Shrink wrapping

Shrink wrap machines cover products with plastic film that shrinks when heated. The plastic forms a tight, protective layer around the product.

First, the machine wraps loose plastic around the item. Then it goes through a heat tunnel where the plastic shrinks to fit perfectly. Shrink wrapping works for single items or groups of products bundled together.

Stretch wrapping (pallet wrapping)

Stretch wrap machines wrap plastic film around pallets of boxes. The plastic stretches as it wraps, creating a tight hold that keeps boxes from falling.

These machines can wrap 20 to 100 pallets per hour. Some spin the pallet while wrapping, while others move around a stationary pallet. Most warehouses use stretch wrapping to prepare shipments.

Strapping machines

Strapping machines tie bundles together with plastic or steel bands. They pull the strap tight and seal it with heat or clips.

Plastic strapping costs less and weighs less. Steel strapping provides more strength for heavy loads.

Cushioning/bubble wrap machines

Cushioning machines make protective packaging materials on demand. They create air pillows, bubble wrap, or foam padding right when you need it.

Making cushioning materials on-site saves storage space. These machines can produce 20 to 100 feet of cushioning per minute. Many shipping departments use them to protect fragile items.

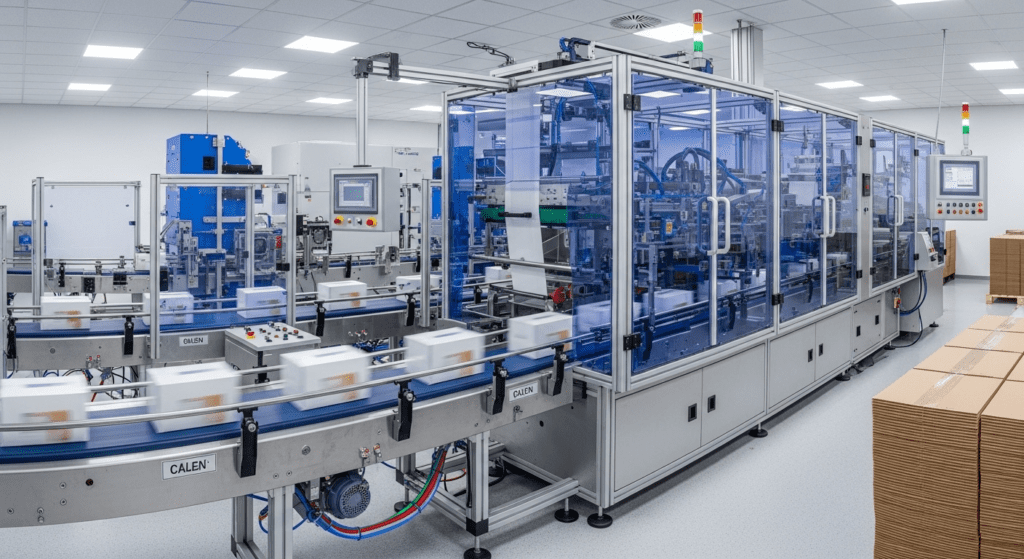

Cartoning and Case Packaging Machines

These machines handle secondary packaging – putting products into boxes or cases. They automate the process of making boxes, filling them, and sealing them shut.

Carton/Case Erectors

Case erectors fold flat cardboard into open boxes. They form the bottom of the box and prepare it for filling.

Most machines handle 10-30 cases per minute. They work with various box sizes by adjusting a few settings.

Case/Carton Sealers

Case sealers close the tops of filled boxes using tape or glue. They apply even pressure for consistent seals.

Random case sealers automatically adjust to different box sizes. Uniform case sealers work fastest with same-sized boxes.

Case Packers (Case Packing Machines)

Case packers place products into boxes in organized patterns. They use robotic arms or mechanical systems to pack accurately.

These machines reduce labor costs by up to 75%. They also prevent injuries from repetitive lifting.

Palletizing Machines

Palletizing machines stack boxes onto pallets for shipping. They create stable loads that won’t fall during transport.

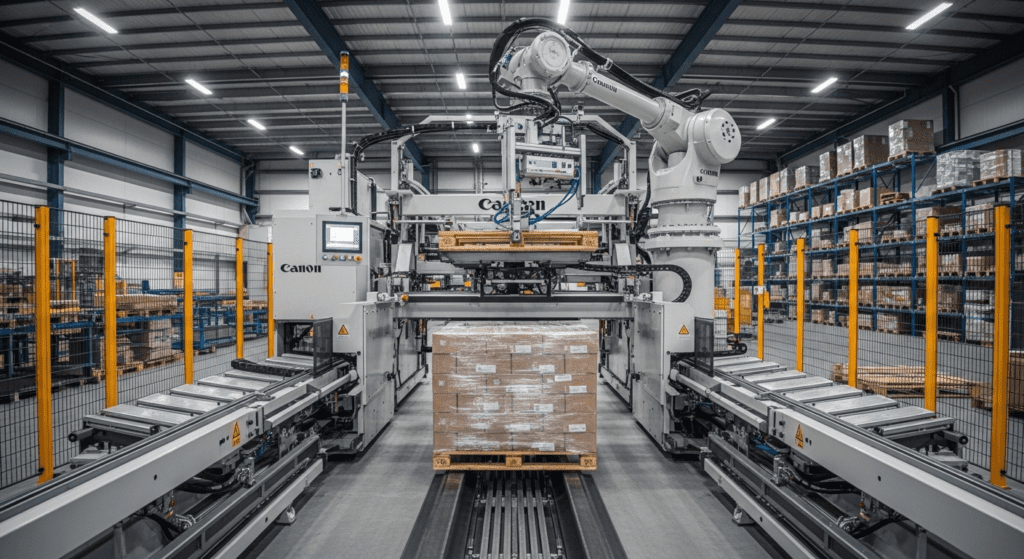

Robotic Palletizers

Robotic palletizers use programmable arms to place boxes. They can handle mixed box sizes and create complex stacking patterns.

A single robot can palletize 8-25 cases per minute. They work well in facilities with many different products.

Conventional/Layer Palletizers

Layer palletizers arrange entire layers of boxes at once. They work faster than robots for single products.

High-speed models handle up to 200 cases per minute. They’re ideal for facilities with high volumes of similar products.

Other/Specialized Packaging Machines

Some products need unique packaging solutions. These specialized machines handle specific packaging formats or add extra features to packages.

Blister Packaging Machines

Blister packaging machines seal products between plastic and cardboard. You see this packaging for pills, batteries, and small hardware items.

They protect products from tampering and moisture. Production speeds range from 20 to 300 blisters per minute.

Skin Packaging Machines

Skin packaging creates a tight plastic film over products on cardboard. The film follows every curve of the product.

This packaging shows products clearly while preventing theft. It works well for tools, toys, and electronic items.

Sachet/Stick-Pak Machines

These machines make small, single-serve packages. They’re perfect for sugar, coffee, medicine, and condiments.

Most produce 30-120 sachets per minute. Some models can make different sizes without changing parts.

Capping Machines

Capping machines put lids on bottles and jars. They handle screw caps, snap caps, and cork stoppers.

Automatic cappers process 20-300 containers per minute. They apply consistent torque to prevent leaks.

Feeding/Unscrambling Equipment

These machines organize products before packaging. They turn jumbled items into neat lines for processing.

Bowl feeders use vibration to orient parts. Bottle unscramblers can handle 50-500 bottles per minute.

Multihead Weighers and Scales

Multihead weighers combine products from multiple hoppers to reach target weights. They minimize product giveaway while maintaining accuracy.

Most systems achieve accuracy within 0.1-1 gram. They work 5-10 times faster than manual weighing.

Inkjet Printers and Coders

These machines print dates, codes, and batch numbers directly on packages. They use quick-drying inks that stick to various surfaces.

Continuous inkjet printers work at speeds up to 1,000 feet per minute. They’re essential for tracking and compliance.

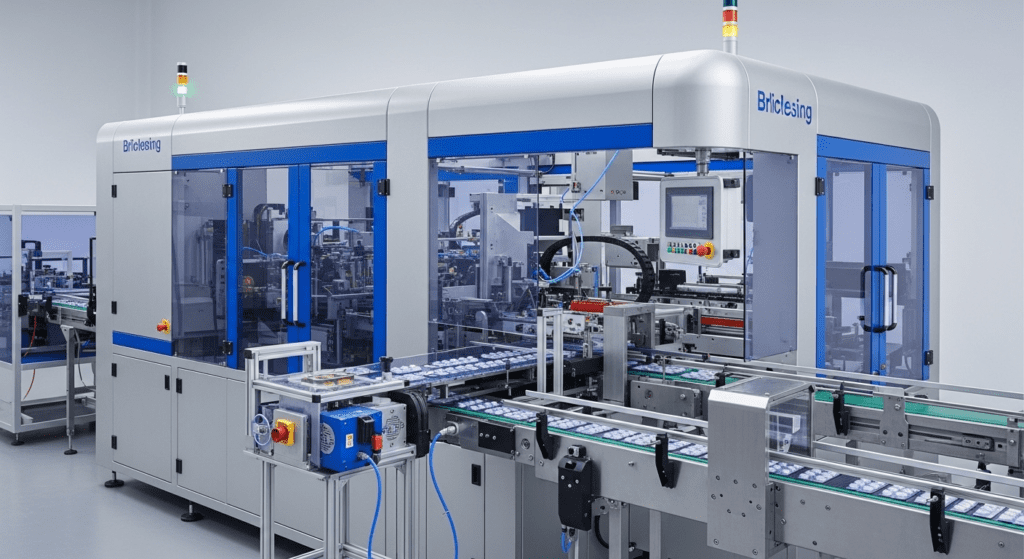

Clamshell/Blister Cartoners

These specialized cartoners insert blister packs or clamshells into cardboard cartons. They often add inserts or instructions too.

They handle 30-120 cartons per minute. Many include vision systems to verify correct packaging.