Choose the right packaging machine by matching product form (solid, liquid, powder) and required speed (units per minute) to machine type (fill-seal, flow-wrap, vertical form-fill-seal). Verify compatibility with packaging material, floor space, budget, and regulatory standards, and confirm easy changeovers plus local service support.

Product Type and Characteristics

Consider the physical nature of your product—solid, liquid, powder, fragile, perishable, etc. Different products often require different packaging solutions.

For example: liquids may need specialized flow or piston fillers to prevent spills, powders often use auger filling systems for accuracy, and fragile items benefit from gentle handling mechanisms。

Packaging Format

Determine the package style you need, as packaging machines are usually designed for specific formats. Whether you plan to pack products in pouches, bottles, jars, cartons, or vacuum-sealed bags, make sure to choose a machine that is compatible with that format.

For instance, a form-fill-seal machine is ideal for creating and filling pouches, whereas a liquid filling line with capping equipment suits bottles, and a cartoning machine is needed to erect and fill cartons.

Production Volume and Speed Requirements

Assess your current production throughput and future growth. A small-batch operation has different needs than a high-volume manufacturing line.

If you produce in bulk, an automated high-speed machine (for example, a form-fill-seal system) may be necessary to keep up with demand while maintaining quality. Conversely, for lower volumes or frequent product changeovers, simpler or semi-automatic machines might be more cost-effective and flexible.

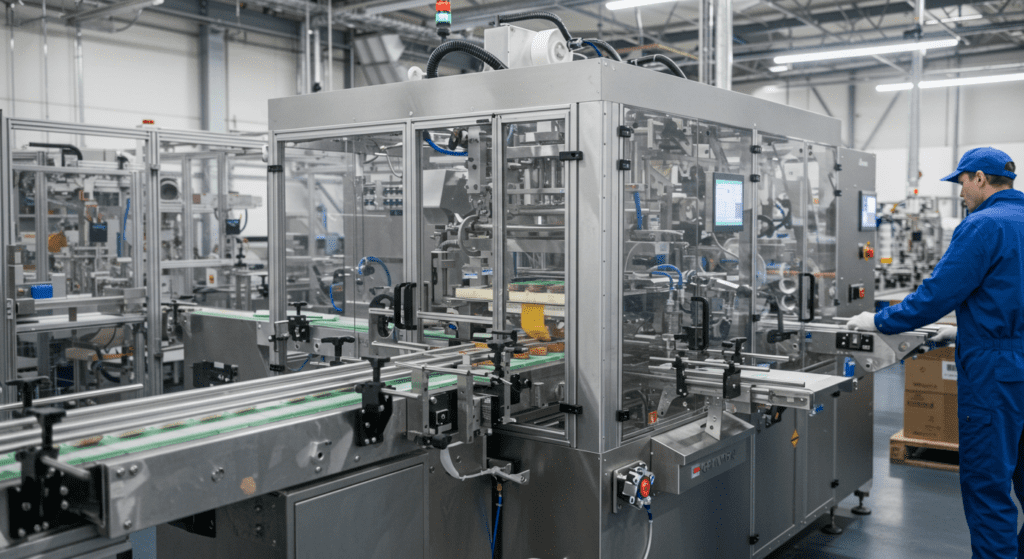

Degree of Automation (Manual vs. Automatic)

Packaging equipment ranges from manual devices to semi-automatic and fully automatic systems.

- Manual or hand-operated machines cost less but require more labor.

- Semi-automatic machines offer a balance. They automate certain steps but still need an operator for others.

- Fully automatic lines have the highest throughput with minimal human input, which is ideal for large-scale production。

Packaging Material Compatibility

Think about the packaging materials you will use (e.g. plastic films, glass bottles, paperboard cartons, foil laminates). Not all machines work with all materials. Select machinery that can handle your chosen packaging materials without issues.

For example, if you plan to use biodegradable or recyclable packaging, ensure the machine can seal or form those materials properly. Some machines are versatile (handling a range of plastics, foils, papers), while others are specialized.

Costs

Establish a budget but consider the total cost of ownership, not just the purchase price. Packaging machines vary from affordable benchtop units to multi-million-dollar automated lines.

High-end machines (e.g. advanced automated systems) cost more upfront but can pay off through labor savings and higher efficiency over time. When budgeting, account for long-term costs like maintenance, spare parts, and energy consumption as well. A more robust machine might cost more initially but could require fewer repairs and consume less energy, saving money in the long run

Maintenance Requirements

All machines need upkeep, so evaluate how easy maintenance is and what support is available. Reliability and support are key to minimizing downtime.

Prefer machines from manufacturers or suppliers that offer strong after-sales service, including readily available spare parts, technical support, and maintenance training. Check if there are local service technicians or if the vendor provides prompt repair services when needed.

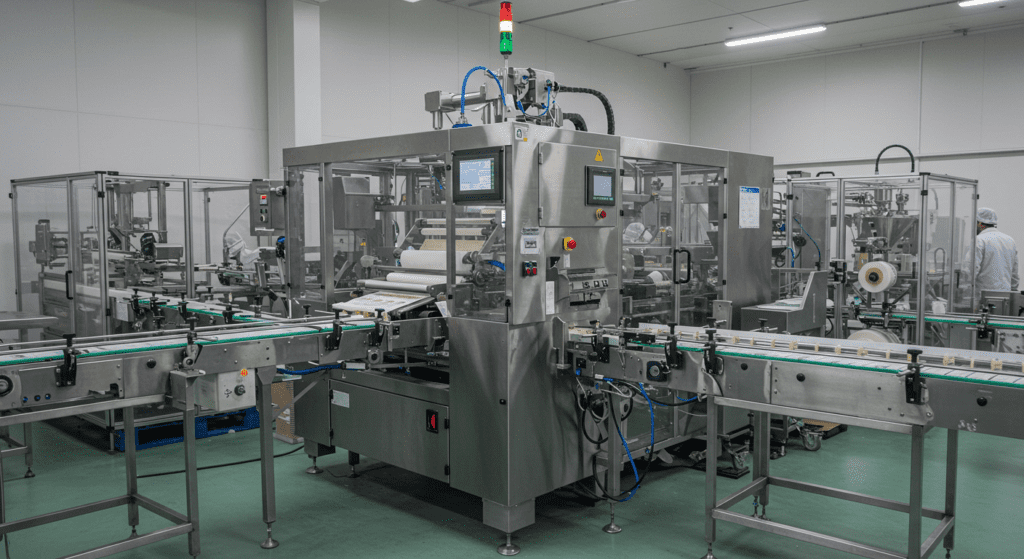

Compliance with Safety and Hygiene Regulations

Packaging equipment must meet the regulatory standards of your industry. Ensure that the machine’s design and construction comply with any health, safety, or sanitation regulations relevant to your product.

For instance, food and beverage packaging machinery should use food-grade materials and be designed for wash-down or sanitation to meet FDA and hygiene standards. Pharmaceutical packaging machines may need to comply with GMP (Good Manufacturing Practice) requirements. Likewise, machines for electrical products might need anti-static features.

Comparison of Packaging Machine Types

| Machine Category | Core Function | Suitable Product Types | Common Industries | Typical Packaging Materials | Relative Speed |

|---|---|---|---|---|---|

| Filling Systems | |||||

| Overflow Filler | Fill (Liquid) | Low-viscosity (water-thin) liquids | Beverage, Chemical, Cosmetics | Bottles (esp. transparent glass/plastic) | Medium-High |

| Piston Filler | Fill (Liquid) | Viscous liquids, creams, pastes, gels | Food, Pharma, Cosmetics | Bottles, Jars, Tubes | Low-Medium |

| Net Weight Filler | Fill (Liquid/Solid) | High-value liquids, bulk products, particulates | Food, Chemical, Paint, Coffee | Pails, Bottles, Bags | Medium-High |

| Auger Filler | Fill (Powder) | Non-free-flowing, dusty, sticky powders | Food, Pharma, Chemical | Bags, Pouches, Rigid Containers | Medium |

| Volumetric Cup Filler | Fill (Granule) | Free-flowing, uniform granules (sugar, rice) | Food | Bags, Pouches | High |

| Multihead Weigher | Fill (Solid) | Discrete items (snacks, candy, frozen food) | Food | Bags, Pouches | Very High |

| Forming & Sealing | |||||

| VFFS Machine | Form, Fill, Seal | Powders, granules, liquids, frozen items | Food, Pet Food, Chemical | Flexible Film (Rollstock) | Medium-High |

| HFFS / Flow Wrapper | Form, Fill, Seal | Single, solid, uniform items (bars, cookies) | Bakery, Confectionery, Medical | Flexible Film (Rollstock) | High-Very High |

| Impulse Sealer | Seal | Thermoplastic films (PE, PP) | General | Bags, Pouches | Low-Medium |

| Constant Heat Sealer | Seal | Thick laminates, foils, gusseted bags | Industrial, Military, Food | Barrier Bags, Coated Papers | Low-Medium |

| Chamber Vacuum Sealer | Vacuum, Seal | Perishables, liquids, meats, cheese | Food Service, Food Processing | Vacuum Pouches | Low-Medium |

| Induction Sealer | Seal (Tamper-Evident) | Products in rigid containers with caps | Pharma, Food, Chemical, Beverage | Foil-lined Caps on Bottles/Jars | High |

| Wrapping Systems | |||||

| Shrink Wrapper | Wrap (Primary) | Retail goods, multi-packs, food | Consumer Goods, Food, Publishing | Shrink Film (POF, PVC) | Medium-High |

| Stretch Wrapper | Wrap (Tertiary) | Palletized loads for transport | Logistics, Distribution, Manufacturing | Stretch Film (LLDPE) | Medium-High |

| End-of-Line | |||||

| Spindle Capper | Cap (Screw-on) | Bottles and jars with screw caps | Beverage, Food, Personal Care | Plastic/Metal Screw Caps | High |

| Chuck Capper | Cap (Screw-on) | Bottles and jars requiring precise torque | Pharma, Chemical, Cosmetics | Plastic/Metal Screw Caps | Medium |

| Horizontal Cartoner | Carton (Secondary) | Solid products (cereal boxes, pizza) | Food, Consumer Goods | Paperboard Cartons | Medium-High |

| Vertical Cartoner | Carton (Secondary) | Top-loaded items (bottles, vials) | Pharma, Cosmetics | Paperboard Cartons | Medium-High |

| Case Erector/Sealer | Case (Tertiary) | Finished products for shipping | All | Corrugated Cases (RSC) | Medium-High |