The cost of a packaging machine ranges from $5,000 to over $250,000 depending on the type, automation level, and production capacity.

small-scale machines (under $5k–$10k) suit startups; mid-tier systems ($10k–$50k) serve SMEs; and multi-lane high-speed equipment ($50k–$200k+) fit large automated plants.

Buyers should compare machines’ capacity and features against these typical ranges. Low-end units may save capital cost but often incur higher labor or maintenance expenses, whereas high-end machines demand bigger investment but deliver greater throughput and reliability.

Cost by Machine Type

Filling machines

- Hobbyist tabletop fillers (single-head, manual pump) can start around \$200–\$1,000.

- Semi-automatic commercial fillers typically run in the \$1,000–\$20,000 range.

- Fully-automatic, multi-head filling lines (for liquids, powders, etc.) start around \$30,000 for basic models and can exceed \$100,000 for robust systems.

Sealing machines

This category includes bag heat-sealers, impulse sealers, and case/carton sealers.

- Simple handheld impulse sealers cost only a few hundred dollars.

- Semi-automatic bag sealers or tabletop L-bar sealers typically cost \$500–\$2,000.

- For case/carton sealing, a basic semi-automatic case taper (carton sealer) is on the order of \$2,000–\$5,000.

- Larger or fully-automatic case sealers (with top and bottom belts, long tables) can range from \$5,000 up to \$30,000.

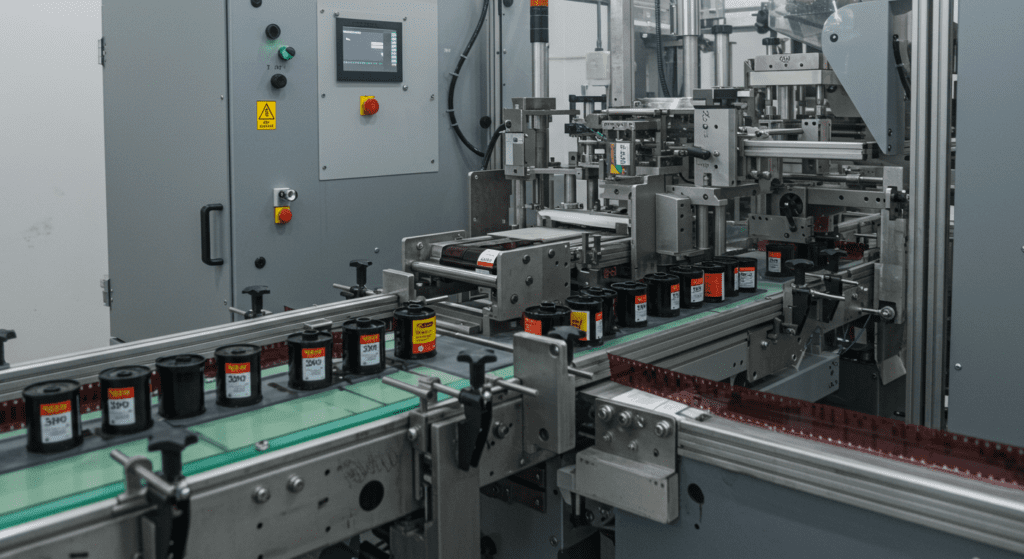

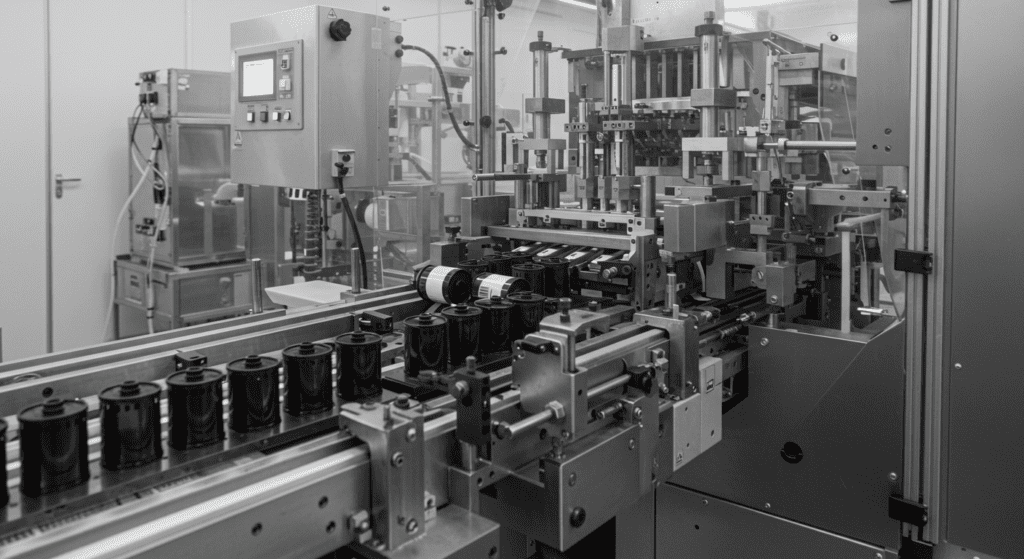

Labeling machines

- Entry-level manual or bench-top label applicators cost a few thousand dollars. For instance, small semi-automatic bottle labelers from Advent run about \$2,000–\$5,000.

- Mid-range semi-automatics or small in-line labelers can be around \$5,000–\$10,000.

- Full high-speed labeling systems (self-adhesive or wrap-around on a conveyor, with registration sensors) typically start at \$10,000–\$20,000 and can exceed \$50,000 for complex pharmaceutical/food-grade models.

Wrapping machines

This includes shrink-wrapping and stretch-wrapping equipment.

Shrink-wrap machines range from small manual heat tunnels to large automatic in-line wrappers:

- Manual shrink-wrap tables cost roughly \$200–\$1,000.

- Semi-automatic shrink systems (with conveyors) run about \$2,000–\$15,000.

- Fully-automatic shrink-labelling/packaging machines start around \$15,000 and can exceed \$50,000.

Stretch-wrap (pallet wrapping) machines are priced differently:

- semi-automatic turntable wrappers typically run \$5,000–\$20,000.

- Fully automated rotary or gantry pallet wrappers (with conveyor integration and film pre-stretch) cost significantly more (often > \$20k).

Case/Box packing machines

Automated case packers (inserting products into cases or cartons) vary greatly.

- Entry-level semi-automatic case packers might start around \$5,000–\$20,000.

- Fully automatic pick-and-place or wrap-around case packing lines are expensive: tens of thousands up to \$100,000+ for sophisticated systems.

Form-Fill-Seal (FFS) machines

Vertical or horizontal FFS machines (for bags, pouches, sachets, etc.) cover a broad spectrum.

- Small vertical FFS for hobbyists can start at \$5,000–\$10,000.

- Medium-capacity FFS machines (single head, semi-automatic) typically cost \$20,000–\$50,000.

- High-speed multi-head FFS (fully automatic, such as multi-lane powder fillers or pouch machines) can range \$50,000–\$200,000+.

Palletizing machines

Automated palletizers (robotic or gantry systems that stack cases/pallets) are capital-intensive.

- An entry-level palletizing robots cost about \$25,000–\$50,000, suitable for light loads or cobot models.

- Mid-range systems (higher payload, faster cycle) are around \$50,000–\$100,000.

- High-end palletizing cells (multiple robots or gantry with full integration) start above \$100,000 and can run well into the several hundred thousands.

- Additional costs for installation (\$5k–\$20k), system integration (\$10k–\$50k), and safety guarding/controls should be factored in.

Scale of Operation

Small-scale (Startups/Micro)

Businesses packing only hundreds of units per day can often start with manual or semi-automatic equipment. For example, a small pasta maker might use a hand-fed bag sealer (\$0.5k–\$2k) and a tabletop labeler (\$2k–\$5k). Overall packaging capital might be under \$10–20k for a basic bench-top line.

Medium-scale (SMEs)

For production of several thousand units/day, semi- and fully-automated machines become cost-effective. A mid-sized beverage co-packer might invest \$50k–\$200k on a semi-auto filler, capper, labeler, and case packer. Used equipment is common at this level: buying a 2–3 year old filler or case packer at 50% of new can cut costs, though with higher maintenance risk.

Large-scale (High-Volume Plants)

Factories running tens of thousands of units/hour install fully integrated automated lines. Packaged food plants, breweries and big pharma lines often involve multi-million-dollar capital investment.

For example, a fully-automated snack pack or pharma bottle line (filling, capping, sealing, labeling, case packing, palletizing) can easily exceed \$1–2 million total. At this scale, per-machine costs are often at the top of each category’s range (e.g. high-speed filler: \$100k+; robotic palletizer: \$100k+).

New vs. Used Equipment

New machines come with full warranty and support, but used machines can slash costs. Buyers of used packaging equipment often see 30–70% savings over new prices.

For example, a used vertical form-fill-seal unit that cost \$100k new might be offered for \$30k–\$70k used. However, second-hand machines may require refurbishing, may lack support, and often carry shorter or no warranties.

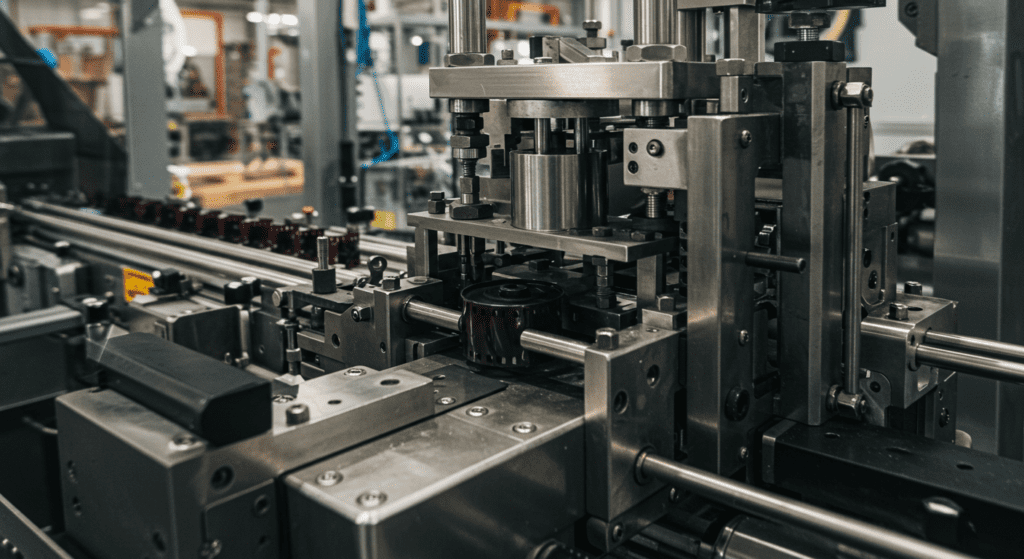

Key Cost Factors

Several factors drive machine price beyond basic type:

- Automation Level: Manual or semi-automatic machines are cheaper but need more labor. Fully automatic systems (PLC controls, servo drives, sensors) cost more up front. In general, costs rise with automation: e.g. a manual shrink-wrapper (\$200–\$1,000) vs. semi-auto (\$2k–\$15k) vs. fully-auto (\$15k–\$50k).

- Production Capacity and Speed: Machines with higher throughput (more heads, faster cycle) require sturdier construction and more sophisticated engineering. A 1-head filler might be <\$20k, but a 4-head rotary filler might be \$50k–\$80k.

- Customization/Special Features: Custom machine lengths, extra lanes, multiple fill heads, in-line weighing, or special handling (cold/sterile environments) add to cost. For example, adding automatic bag feeders, laser printers, or nitrogen flushing to a machine can each add \$2k–\$10k+.

- Material and Construction: Standard carbon-steel machines are cheapest; food/pharma-grade machines use 304/316 stainless steel and sanitary design (higher cost). Explosion-proof or chemical-resistant coatings add to base price.

- Brand and Support: Well-known OEMs (Bosch, IMA, Tetra Pak, Krones, etc.) charge premiums reflecting engineering, quality, and warranty. Lesser-known manufacturers can be cheaper but may compromise on service.

- Facility Integration: Costs for conveyors, robotic feeders, sorters, guarding, and electrical/control integration are often separate. These add-ons can each cost \$1k–\$10k.

Optional Add-Ons and Maintenance

Add-Ons

Common optional extras include in-line checkweighers, metal detectors, barcode or date-printing systems, automated conveyors, bulk product feeders, and palletizers.

For example:

- A label printer/coder may add \$3k–\$8k

- A full in-line checkweigher ~\$5k

- An automated pallet conveyor/piler could be \$10k–\$20k

Maintenance Costs

Buyers should budget ongoing maintenance at roughly 3–5% of machine cost per year. Spare parts (belts, seals, sensors) typically run hundreds to a few thousand dollars annually.

For example:

- A shrink-tunnel repair might cost \$200–\$1,000, and robotic palletizer maintenance is often in the low thousands per year.

- Service contracts (annually \$1k–\$5k or more) can reduce downtime.

- Warranty extensions are also available at extra cost.

- Consumables (films, labels, lubricants) and energy usage (heat tunnels can be power-hungry) add to total cost of ownership.

Typical Cost Ranges by Machine Type and Scale

| Machine Type | Small-Scale (New) | Medium-Scale (New) | Large-Scale (New) |

|---|---|---|---|

| Filling | \$0.2k–\$1k | ~\$1k–\$20k | \$30k–\$100k+ |

| Case/Carton Sealing | ~\$0.2k–\$0.5k (hand/impulse) | ~\$2k–\$5k | \$10k–\$30k |

| Labeling | ~\$2k–\$5k | ~\$5k–\$10k | >\$20k (high-speed) |

| Wrapping (Shrink) | ~\$0.2k–\$1k | ~\$2k–\$15k | \$15k–\$50k |

| Case Packing | ~\$5k–\$20k (semi-auto) | ~\$20k–\$50k | \$50k–\$200k+ |

| Form-Fill-Seal | ~\$5k–\$20k | ~\$20k–\$50k | \$50k–\$200k+ |

| Palletizing (robots) | ~\$25k–\$50k | ~\$50k–\$100k | \$100k+ |

*Table: Approximate new machine cost ranges by type and operation scale (used prices roughly 30–70% of new).