Heat sealing machines work by applying heat and pressure to bond thermoplastic materials. The device heats sealing bars or jaws, which melt the contact surfaces of packaging films. When pressed together, the melted layers fuse. As the material cools, it forms a strong, airtight seal that protects contents.

What Is Heat Sealers

A heat sealer is a device that uses heat to join thermoplastic materials together by melting their surfaces. These machines create airtight, watertight seals on plastic bags, pouches, and packaging materials.

Think of it like a hot iron that presses two pieces of plastic together until they melt and stick. The result is a strong, permanent bond that keeps products fresh and protected.

How Heat Sealers Work

Heat sealers work by applying controlled heat and pressure to thermoplastic materials for a specific amount of time. The process involves three key elements: temperature (usually between 250-500°F), pressure (typically 40-80 PSI), and dwell time (0.5-3 seconds).

When you place two pieces of plastic between the sealing bars, the machine heats up the contact area. The plastic softens and melts slightly at the exact spot where the bars press down.

As the materials cool down (which happens in just 1-2 seconds), they fuse together creating a strong bond. This seal is often stronger than the original material itself.

The sealing bars are usually coated with Teflon or similar non-stick materials. This prevents the melted plastic from sticking to the machine parts.

Sealer Operation Modes

Manual Heat Sealers

Manual heat sealers require you to activate each seal by hand, either by pressing down a bar or squeezing a handle. These machines seal one package at a time.

They’re perfect for small businesses or low-volume operations. You control exactly when and where the seal happens.

Most manual sealers cost between $50 and $500. They can seal 5 to 20 packages per minute, depending on the operator’s speed.

Continuous Sealers

Continuous sealers use motorized belts to move packages through the sealing area automatically. You just feed the bags into the machine, and it does the rest.

These machines can seal 20 to 60 feet of material per minute. They work great for high-volume operations where speed matters.

The belts keep moving while the heating elements stay at a constant temperature. This design allows for non-stop sealing without waiting between packages.

Semi-Automatic Sealers

Semi-automatic sealers combine manual loading with automatic sealing cycles. You place the package in position, then the machine takes over.

A sensor or foot pedal triggers the sealing process. The jaws close, apply heat, cool down, and open automatically.

These machines seal 15 to 40 packages per minute. They reduce operator fatigue while maintaining control over package placement.

Types of Heat Sealers

The main types of heat sealers are impulse sealers, constant heat sealers, band sealers, and vacuum sealers.

Handheld Heat Sealers

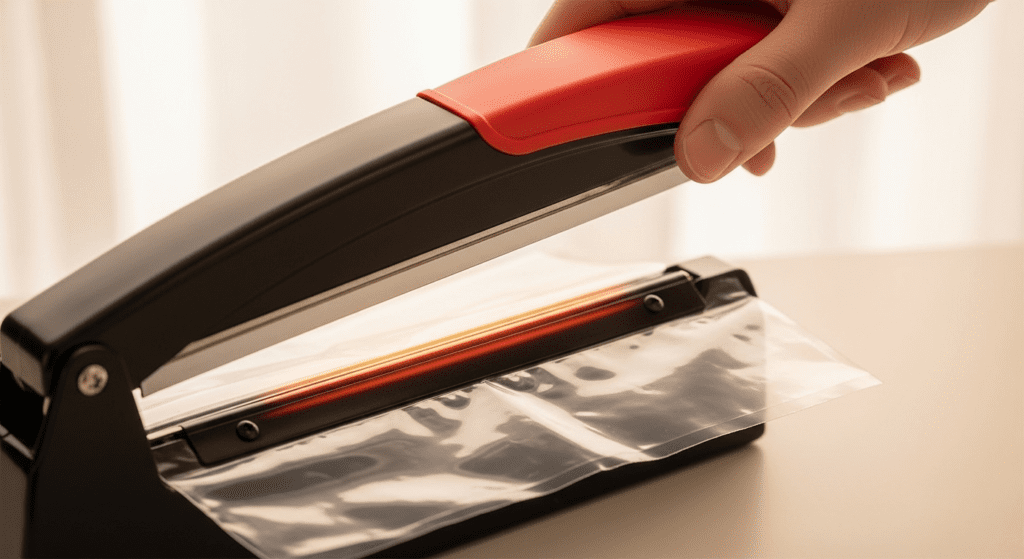

Handheld heat sealers are portable devices that look like large staplers or small irons. They weigh 1 to 3 pounds and plug into standard outlets.

You squeeze the handle to bring heated jaws together on the material. Most models heat up in 30 to 60 seconds and create seals 2 to 8 inches long.

These sealers cost $20 to $150. They’re ideal for sealing snack bags, craft projects, or emergency repairs.

Foot Pedal Heat Sealers

Foot pedal sealers free up both hands for positioning packages while your foot controls the sealing action. The machines sit on tables or stands at comfortable working heights.

Pressing the pedal activates the sealing bar. This design increases productivity by 25% to 40% compared to manual hand-operated sealers.

These units typically create seals from 12 to 40 inches long. Prices range from $200 to $2,000 depending on seal length and features.

Impulse Sealers

Impulse sealers only heat up during the actual sealing process, using electricity to heat a thin wire for 1 to 3 seconds. The wire cools down immediately after each seal.

This on-demand heating saves energy and prevents burns. The machines stay cool to the touch between seals.

Impulse sealers work best with thin materials under 10 mil thickness. They create clean, narrow seals about 2mm to 5mm wide.

Constant-Heat Sealers

Constant-heat sealers maintain their jaws at sealing temperature continuously throughout operation. They’re ready to seal instantly without warm-up time between packages.

These machines work faster than impulse sealers for thick materials. They can handle plastics up to 20 mil thick.

The trade-off is higher energy use and safety concerns. Operators must be careful around the always-hot sealing bars.

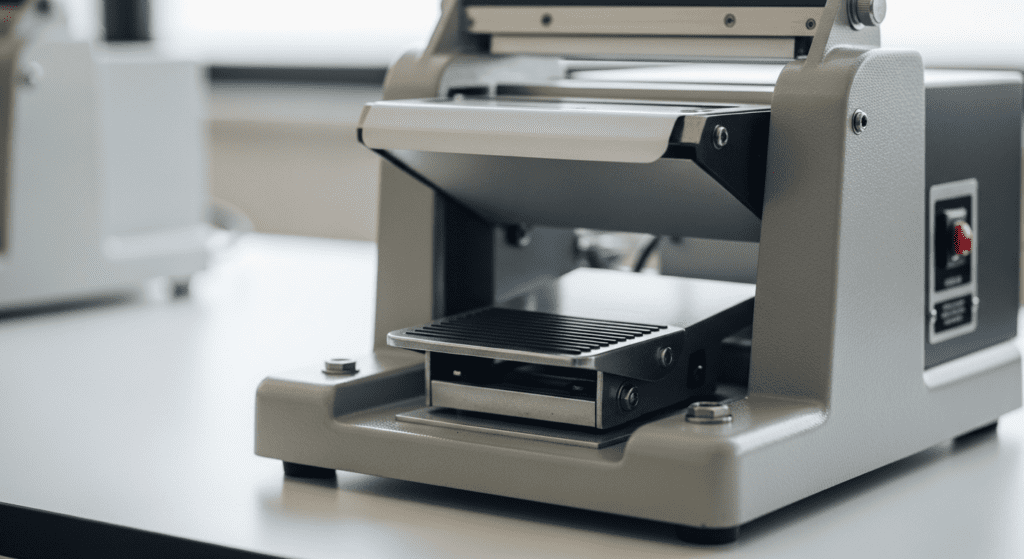

Hot-Bar Sealers

Hot-bar sealers use heated metal bars that press down onto materials with precise temperature and pressure control. They create wide, strong seals from 5mm to 25mm.

These machines excel at sealing thick, multi-layer materials. They can join different types of plastics together reliably.

Temperature controllers maintain accuracy within 2°F. This precision ensures consistent seal quality across thousands of packages.

Ultrasonic Sealers

Ultrasonic sealers use high-frequency sound waves (20 to 40 kHz) to create friction heat directly inside the material. No external heat source is needed.

The vibrations generate temperatures up to 480°F at the molecular level. This process takes just 0.1 to 0.5 seconds per seal.

These machines work especially well with synthetic fabrics and films. They create strong seals without damaging heat-sensitive materials.

Induction Sealers

Induction sealers use electromagnetic fields to heat aluminum foil liners inside bottle caps or container lids. The process creates tamper-evident seals in 0.5 to 3 seconds.

A coil generates a magnetic field around the container opening. This field heats only the foil, which then bonds to the container rim.

These sealers work with glass, plastic, and metal containers. They’re common in pharmaceutical, food, and cosmetic packaging lines.

Continuous Sealers

Continuous sealers (also called band sealers) use rotating belts or wheels to move packages through a heated sealing zone. They never stop moving during operation.

Speed adjustments range from 0 to 40 feet per minute. Different belt materials handle various package types and weights.

These machines often include printing capabilities. They can add date codes, batch numbers, or logos while sealing.

Hot Wire Sealers

Hot wire sealers use a heated wire to simultaneously cut and seal plastic materials. The wire reaches temperatures of 600°F to 1000°F.

One pass creates a sealed edge and separates the material. This eliminates the need for separate cutting operations.

These sealers work great for making bags from tubular film. They’re also perfect for trimming excess material while sealing.

Cold Sealers

Cold sealers use pressure-sensitive adhesives instead of heat to create seals. They press materials together with 40 to 80 PSI of force.

These machines work with pre-coated cold-seal materials. The adhesive only sticks to itself, not to the product inside.

Cold sealing protects heat-sensitive items like chocolate or medical supplies. Seal times range from 0.5 to 2 seconds.

Comparison of Heat-Sealing Technologies

| Technology | Temperature Range | Seal Time | Best For | Energy Use | Cost Range |

|---|---|---|---|---|---|

| Impulse | 250-400°F | 1-3 seconds | Thin films (<10 mil) | Low | $50-$1,000 |

| Constant Heat | 300-500°F | 0.5-2 seconds | Thick materials | High | $200-$3,000 |

| Ultrasonic | No external heat | 0.1-0.5 seconds | Synthetics | Medium | $2,000-$20,000 |

| Hot Bar | 250-450°F | 1-4 seconds | Multi-layers | Medium | $500-$5,000 |

| Induction | 300-400°F | 0.5-3 seconds | Cap sealing | Low | $1,000-$15,000 |

| Hot Wire | 600-1000°F | 0.5-1 second | Cut & seal | High | $300-$2,000 |

| Cold Seal | Room temp | 0.5-2 seconds | Heat-sensitive | Very Low | $500-$3,000 |

Sealable Materials

Heat sealers work with many different thermoplastic materials. Each material requires specific temperature and pressure settings for optimal results.

Here are the most common sealable materials:

- Polyethylene (PE) – Seals at 275-325°F. Used in grocery bags, food packaging, and industrial films. Most common plastic for heat sealing.

- Polypropylene (PP) – Needs 325-375°F. Found in snack bags, medical packaging, and retail pouches. Creates very strong seals.

- Polyethylene Terephthalate (PET) – Requires 425-475°F. Used in display packaging and high-barrier applications. Offers excellent clarity.

- Nylon (Polyamide) – Seals at 425-475°F. Common in vacuum bags and high-temperature applications. Provides superior puncture resistance.

- PVC – Works at 275-325°F. Found in blister packs and clamshells. Easy to seal but less environmentally friendly.

- PS – Needs 325-375°F. Used in food containers and protective packaging. Creates rigid, clear seals.

- Aluminum Foil – Requires special coatings to seal at 300-400°F. Provides excellent barrier properties. Often combined with plastic layers.

- Film/Foil Laminates – Seal at 300-425°F depending on materials. Combine barrier properties of foil with sealability of plastic. Common in coffee and snack packaging.

- Paper/Foil Laminates – Need 325-400°F. Used in medical device packaging. Allows sterilization while maintaining seal integrity.

- Medical Papers – Seal at 350-425°F with special coatings. Designed for sterile barrier systems. Must meet strict healthcare standards.