The main difference between horizontal and vertical form-fill-seal machines is the direction of packaging. Horizontal machines package products while lying flat and are best for solid, stable items like bars or pouches. Vertical machines package items from top to bottom and are ideal for powders, liquids, or free-flowing products.

What is Horizontal Form-Fill-Seal Machine

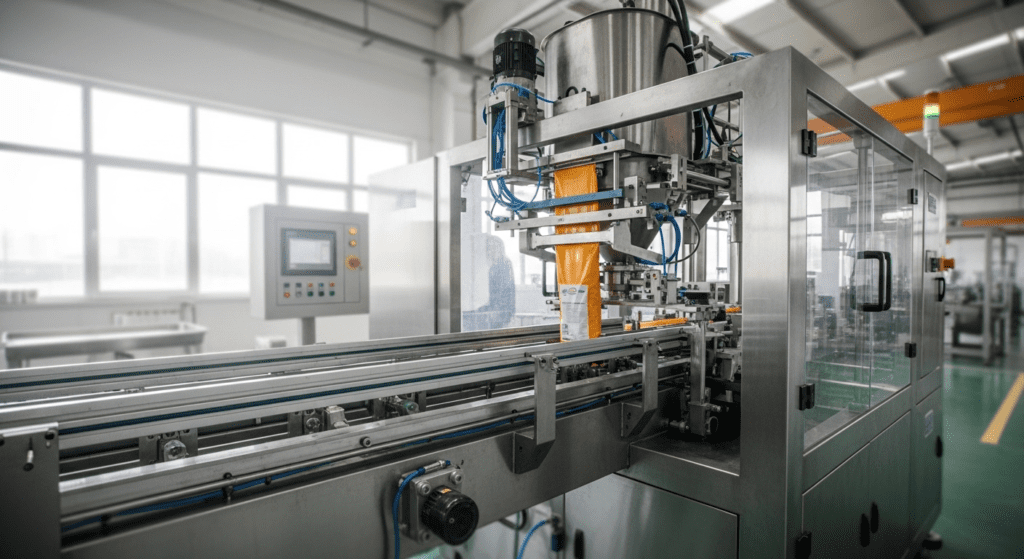

A Horizontal Form-Fill-Seal (HFFS) machine is packaging equipment that creates, fills, and seals packages in a horizontal direction. The machine pulls packaging film horizontally along a conveyor system.

These machines work by feeding flat film through the system where it’s shaped into pouches or bags. Products are then placed into these formed packages before the machine seals them shut. The entire process happens while the packaging moves horizontally through the machine.

HFFS machines are particularly good at handling solid items that need gentle treatment. They excel at packaging products like chocolate bars, cookies, medical devices, and pre-formed containers. The horizontal layout allows products to be placed carefully without dropping them from a height.

What is Vertical Form-Fill-Seal Machine

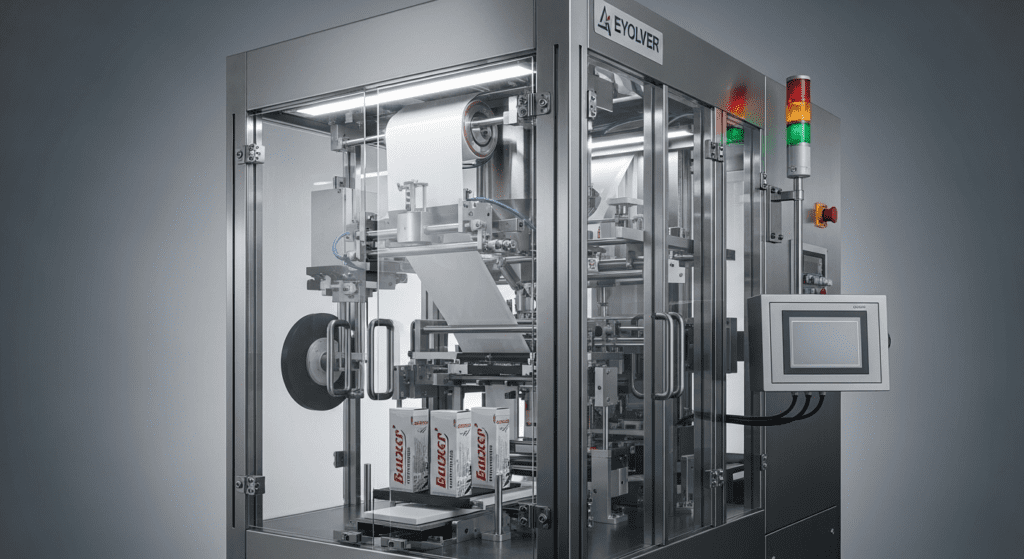

A Vertical Form-Fill-Seal (VFFS) machine creates packages by pulling film downward in a vertical direction. The film wraps around a forming tube to create a pouch shape.

These machines use gravity to their advantage. Product flows down through the forming tube into the package being created below. Once filled, the machine seals the top of the package and cuts it free. The sealed top then becomes the bottom of the next package.

VFFS machines work best with products that flow easily. They’re ideal for packaging snacks, coffee, rice, powders, and liquids. The vertical design means these machines take up less floor space than their horizontal counterparts.

HFFS vs VFFS

Suitable Products

VFFS machines work best with products that flow freely and can drop by gravity. This includes:

- Snack foods like chips and popcorn

- Granular products like rice, sugar, or coffee

- Powders and small parts

- Frozen vegetables

- Candy and nuts

HFFS machines handle products that VFFS can’t:

- Products that need to stay horizontal (like syringes or tools)

- Liquids in rigid containers

- Multiple items that need precise placement

- Delicate items that could break if dropped

- Products requiring modified atmosphere packaging

Packaging Formats

VFFS machines typically create:

- Stand-up pouches

- Pillow bags

- Gusseted bags

- Four-side seal pouches

HFFS machines offer more variety:

- Thermoformed trays

- Blister packs

- Vacuum skin packages

- Flow wraps

- Pre-made container filling

The horizontal design of HFFS allows for more complex package shapes and multi-compartment designs that would be impossible with vertical systems.

Speed (throughput)

VFFS machines generally run faster for simple bag styles. A typical VFFS can produce 30 to 300 bags per minute, depending on product and bag size. Some high-speed models reach 400 bags per minute for small packages.

HFFS machines usually run slower but handle more complex packaging. Standard speeds range from 15 to 100 packages per minute.

Space Requirements

VFFS machines win on floor space. Their vertical design means a smaller footprint—typically 6 to 12 square feet for standard models. This makes them ideal for facilities with limited floor space.

Capital Cost

VFFS machines typically cost less than HFFS machines. The simpler mechanical design of vertical machines contributes to their lower cost. They have fewer moving parts and less complex control systems than horizontal machines.

HFFS machines need more room. A typical system requires 20 to 60 square feet or more, depending on features.

Maintenance

VFFS machines have fewer moving parts, making maintenance simpler. Regular tasks include:

- Cleaning product contact surfaces (daily)

- Checking and replacing seal bars (monthly)

- Lubricating moving parts (weekly)

- Replacing cutting blades (every few months)

Most operators can handle routine VFFS maintenance after basic training. Annual service costs typically run 3% to 5% of the machine’s purchase price.

HFFS machines need more attention due to their complexity. Maintenance includes:

- Calibrating forming stations (weekly)

- Checking vacuum systems (daily)

- Maintaining heating elements (monthly)

- Adjusting chain tensions (weekly)

- Cleaning and replacing forming tools (as needed)

HFFS maintenance often requires specialized technicians. Annual service costs can reach 5% to 8% of purchase price.

Material Efficiency

VFFS machines excel at material efficiency. They create packages directly from roll stock with minimal waste. The continuous forming process means very little film is lost between packages.

HFFS machines may use slightly more packaging material. The horizontal process sometimes requires larger film widths to accommodate product placement. Some package styles, like stand-up pouches, also use more material than simple pillow bags.

Summary Table of Key Differences

| Characteristic | Horizontal FFS (HFFS) | Vertical FFS (VFFS) |

|---|---|---|

| Mechanism | Forms/seals bags horizontally on a conveyor. | Forms/seals vertically over a tube (gravity-fed). |

| Suitable Products | Solid, irregular, heavy items (bars, baked goods, devices). | Free-flowing/powder/liquid (coffee, sugar, detergents). |

| Common Formats | Flow-wrapped pillows, 3- & 4-side seal sachets, stand-up pouches. | Pillow bags, quad-seal, stickpack, sachets, spouted pouches. |

| Speed (throughput) | Very high (up to ~300–400 packs/min). | Moderate (typically ~50–100 packs/min). |

| Footprint | Larger (long, horizontal layout). | Compact (vertical orientation). |

| Capital Cost | Higher (more complex, customization). | Lower (simpler design). |

| Material Efficiency | Typically less trim waste. | Slightly more trim waste sometimes. |

| Maintenance | More components to service (higher maintenance). | Simpler design (lower maintenance). |

| Typical Industries | Food (snacks, bakery), cosmetics, hardware, pharma. | Food (coffee, powdered), beverage, chemicals, pharma. |